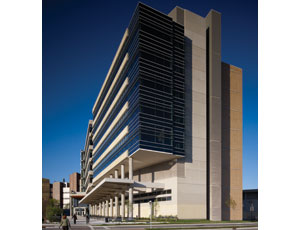

This $155-million project is the first of three phases for the new Wisconsin Institutes for Medical Research at the University of Wisconsin School of Medicine and Public Health. The project included master planning, design and construction of a 469,000-sq-ft East Tower, an interdisciplinary research facility, at the center of the UW-Madison health sciences campus. The new seven-story tower houses the UW Paul P. Carbone Comprehensive Cancer Center. The building enhances connectivity between the UW Hospital and Clinics and the Health Sciences Learning Center and serves as a catalyst for interdisciplinary and translational medicine. The new facility allows scientists and clinicians from varying disciplines to work in close proximity and quickly translate research discoveries from the bench to the bedside and back again.

The project used 3D modeling and BIM tools for the coordination of various mechanical, electrical, and plumbing tasks.

Owner: University of Wisconsin, Madison, Wis.

General Contractor: The Boldt Co., Appleton, Wis.

Design Firm: HOK, Chicago

The project had an average recycling rate of 75% with over 8,000 tons of materials having been recycled. Furthermore, an additional 4.7 tons of copper totaling $19,753 was donated to the American Family Childrens Hospital, a neighboring construction project that WIMR shared staging areas with in order to reduce impact to the community. The project also supported the academic community by hosting eight local interns and a UW civil and environmental engineering field observation program at various times during construction.

To keep on schedule, Boldt incorporated Last Planner scheduling techniques into the project schedule, which focused on a six-week look ahead taken from the master project schedule.

In order to deal with both permeable and impermeable areas of the site, the project team had to adapt from a suction method of dewatering to a wicking and deep well system. As such, a utility tunnel was constructed beneath the lowest level, and was completely submersed below the water table. The tunnel was designed to be watertight and was ballasted to ensure that it would not float to the top of the water table.

The high level of vibration resistance and the relatively wide column spacing made it necessary for the team to deal with over 30 different concrete mixes. Rebar cages were so dense that over 6,000 #11 couplers were used on the project. In the end, WIMR used over 55,000 cu yds of concrete for the Phase 1 project.

Post a comment to this article

Report Abusive Comment