The Museum of Science and Industry in Chicago celebrated its 75th anniversary with the announcement of two new, large, and technologically advanced exhibits. The existing HVAC was insufficient, so a water-cooled electric chiller was needed to handle the increased cooling load.

The museum outlined three main criteria for an upgraded central cooling plant: First, it had to be able to cool the existing load and also have room for future expansion. Second, it had to be able to be installed in phases. Third, it had to be as energy-efficient as possible.

The design engineer used energy-modeling software to present various plant and equipment options to help the museum‘s management choose a system.

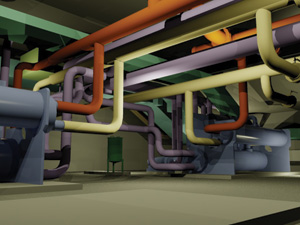

Early on, the project’s design firms and contractors realized that building information modeling (BIM) would be vital to the project’s success, so much of the shop-drawing coordination was done with 3D models instead of paper shop drawings. The design and construction teams met and discussed coordination issues, interferences, and design changes while viewing and editing the 3D model. This enabled immediate agreement and quick changes.

It also allowed ductwork and piping to be pre-fabricated in large sections so that all piping and sheet-metal could be installed efficiently and fit correctly the first time.

To be energy efficient, the $5.9-million central plant uses variable frequency drives on all pumps and compressor motors and the system is designed as a variable primary flow plant with a twist. First, a pressure independent control valve (PICV) is used to trim flow to chillers, thereby running equipment most efficiently.

Owner: Museum of Science and Industry

General Contractor: Hill Mechanical Corp., Franklin Park, Ill.

Design Firm: McGuire Engineers, Chicago

Another PICV in the chilled-water bypass line minimizes bypassed chilled water when the building’s flow is less than the minimum chiller required flow.

The valves are controlled by the building-automation system, which monitors flow to the building and anticipates the best way to operate the equipment based on the outside conditions and historical cooling conditions.

On the condenser-water side, the plant uses a chemical-free water treatment system. Also, the plant uses the cooling towers in the winter for free cooling.

The museum plans to turn the central cooling plant into a learning experience by making it a permanent exhibit that will give visitors an up-close look at a fully functional central cooling plant with color coded piping and interactive displays.

Post a comment to this article

Report Abusive Comment