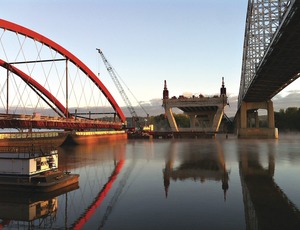

Offsite construction of arch span steel allowed builders of Hastings Bridge, said to be the longest free-standing tied-arch span in North America, to execute one of the heaviest bridge moves ever in the U.S. It also accelerated the schedule and minimized environmental disturbance during construction of the 545-ft-long main span, which straddles the Mississippi River.

Float-in and lift were completed in a 48-hour window during which the span was transported downstream and placed in its final position. Operations began with self-propelled modular transporters lifting the span off shoring towers and conveying it to a flotilla of barges.

Crews next deployed tugboats, skid rails and jacks to maneuver the assembly into position. They then connected strand jacks at each corner to lift the 3,300-ton superstructure 55 ft and lock it off atop concrete piers. With the structure in place, concrete knuckles and ties were placed and sequentially post-tensioned. After casting in place concrete tie girders and decks, crews made final adjustments prior to opening the bridge to traffic.

In addition to its tied arch, Hastings features freestanding vertical steel-arch ribs whose stiffened box configuration eliminated requirements for traditional bracing.

Its main piers consist of concrete delta-style frames, with knuckle connections framing the superstructure into each pier and stabilizing the ribs.

The bridge's post-tensioned tie girder and steel-girder grid floor system include transverse floor beams and full-depth longitudinal stringers to meet stringent redundancy requirements. The structure contains no fracture-critical elements. For every structural element in net tension, a redundant load path is provided.

To address aesthetic concerns, a visual quality team sought consensus among community members, seeking to ensure that the bridge components were compatible with both their natural surroundings and historic Hastings, Minn.

Amenities across the bridge range from custom rails to accent lighting and public murals.

Built for a 100-year service life, Hasting Bridge accommodates four lanes of traffic and a 12-ft-wide pedestrian and bike path.

Hastings Bridge, Hastings, Minn.

Key Players

Owner Minnesota Dept. of Transportation, St. Paul

General Contractor Lunda Construction, Rosemount, Minn.

Designer Parsons, Minneapolis

Post a comment to this article

Report Abusive Comment