A team of researchers from three universities are developing an integrated offshore mooring system that could potentially secure hundreds of floating wind turbines for a commercial wind farm.

“To our knowledge, this concept of using anchors for multiple turbine platforms is new,” says Sanjay Arwade, associate professor of civil engineering at UMass Amherst, who is conducting research for a three-year, $500,000 project funded by the National Science Foundation.

The research team includes Don DeGroot, professor of civil engineering at UMass, Melissa Landon, associate professor of civil engineering at the University of Maine, and Charles Aubeny, professor of civil engineering at Texas A&M University.

Based on the DOE's goal of achieving 20% wind by 2030 or an estimated 54 gigawatts of offshore wind, the equivalent of tens of thousands of wind turbines will be required over the next few decades.

“To meet that goal, a significant fraction [of the turbines] will be put on floating platforms. The biggest barrier to the development of floating systems is cost,” Arwade says. “Offshore systems [such as this] that can bring down initial capital cost of offshore wind farm development will help the industry move forward.”

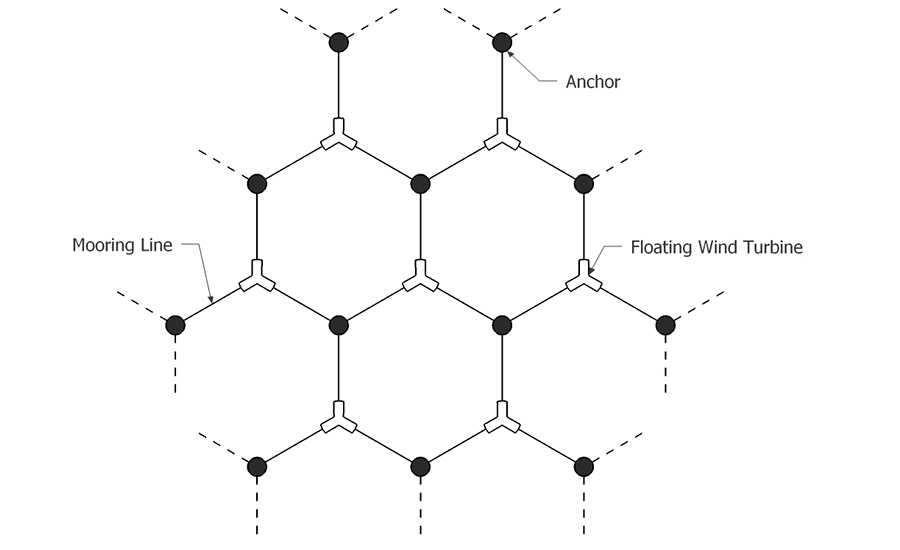

The team of structural and geotechnical engineers is now working on developing different geometries of wind farm layout for which the multi-line concept would work. “We’re considering how to position wind turbines so it’s feasible to interconnect the mooring systems and developing estimates of the loads and forces on the anchors from this complex dynamics problem of the floating system being driven by wind and waves.”

Offshore floating wind turbine blades can be 70 meters (230 ft) to 90 m (295 ft) in length with towers 90 to 120 m (394 ft) tall. “The mooring system keeps the floating platform in position within specified tolerances.” Arwade says.

The big question is how to scale up offshore projects from demo- to wind-farm size, in which multiple turbines float close to each other, says industry partner, Leo Bello, vice president at Houston-based subsidiary of Global Maritime Vryhof® in the Netherlands. “To reduce the environmental impact, one anchor would be shared by multiple floaters [with the mooring lines extending] like a spider web,” he says.

“The ideal mooring system would be assembled on an anchor-handling vessel, then installed by lowering it to the seabed and dragging it, similar to how a recreational vehicle is anchored,” Bello says. “Since anchor-handling vessels are readily available and cost 20% less than large offshore installation vessels, this system is expected to lower installation cost,” he says.

Foundation options under study include drag-embedment anchors, caissons embedded using a suction pump, or piles installed using an underwater hydraulic hammer.

Post a comment to this article

Report Abusive Comment