We are at a turning point in the construction industry. Organizations are choosing to embrace the technology revolution to win more projects with more profitable margins, deliver them more efficiently and safely, and develop a sustainable competitive advantage. However, construction project supply chains face multiple challenges that can impact their efficiency and effectiveness.

A supply chain includes all the materials and parts that are made into a product and distributed up the chain, encompassing manufacturers, suppliers, designers, contractors, and owners. In practice, anyone involved in designing, planning, purchasing, executing, or managing project delivery is part of a supply chain. Being one part of a supply chain can be hard enough, but managing an entire construction supply chain, with its many relationships and interfaces, is much more challenging.

Good supply chain management means that materials, resources, and services are delivered on time and within budget, enabling contractors to deliver projects efficiently and safely. Construction technology, when deployed as part of a robust digitization strategy, can help achieve substantial financial benefits including lower overall costs, higher productivity, better resource management, and improved financial insight and analysis. Construction projects can be complex, involving numerous interdependent activities and a wide range of materials, equipment, and resources. Coordinating the timely delivery of these resources to the right place at the right time can be a significant challenge. Here are some of the ways that digital technology can help.

Digital models and workflows enable construction teams to quickly assess the impact of an event and communicate corrective actions to get things back on track.

Project Bidding

During the bidding stage, contractors can use 3D models to easily see errors and omissions, or to detect likely issues with future execution. Design models can be transformed quickly and easily into constructible models that the bid team can use to produce accurate estimates of quantities and costs. 3D models can also be linked to the project schedule to generate a 4D model, which enables the team to review, validate, and optimize the path of construction and site logistics.

Digital construction models promote a better understanding of the project requirements by project stakeholders, which can foster dialogue between clients and bidders. Improved communication results in fewer variations, change orders, delays, and disruption during project execution. Clients will receive robust, reliable bids that are more competitive, and contractors will win projects that are likely to be profitable for them.

Project Execution

3D and 4D digital construction models continue to add value when a project reaches the development site. It is said in the military that no plan survives contact with the enemy, and a construction project schedule is no different. Events happen on site that require tasks and activities to be continually adjusted to suit what happens out in the field – the weather could be worse than expected, deliveries might be late, and the client could request changes.

Digital models and workflows enable construction teams to quickly assess the impact of an event and communicate corrective actions to get things back on track. A typical use case employs a 4D model to regularly compare planned and actual progress, along with earned value. The project manager will receive near real-time insights into project performance, and can take appropriate action much earlier than with a traditional, nondigital approach.

Many stakeholders can benefit from using digital 4D information. For example, the construction sequence can be shared with contractors, subcontractors, and field crews by using a web browser or phone app. They can see areas of concern and potential issues virtually, before they occur in the field, and collaborate to fix them. During a recent Highway Engineering Exchange Program webinar, Matt Blake from Lane Construction said, “From a contractor’s perspective, utilizing model-based delivery enables more accuracy, transparency, collaboration, timely data, and streamlined and repeatable processes.”

Changes will always happen, but digital technology helps to minimize the impact.

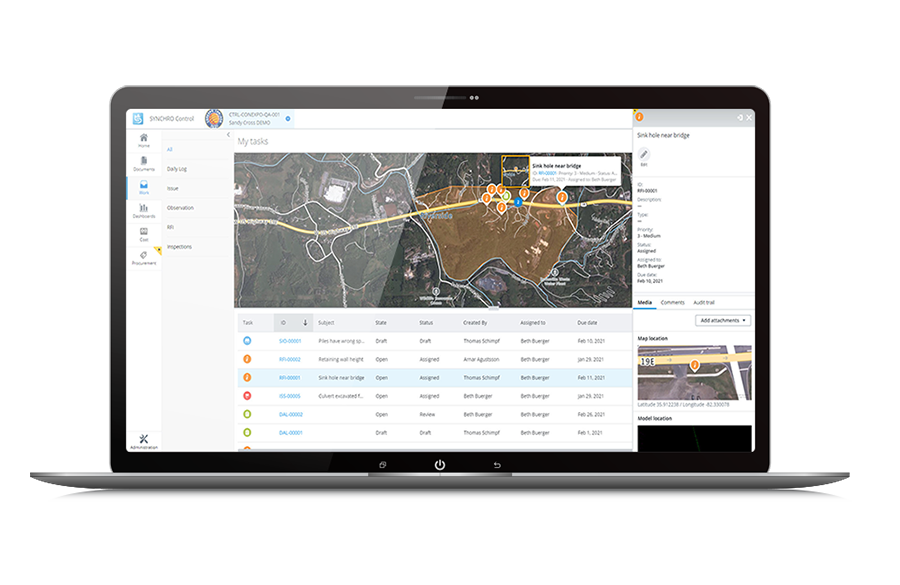

Mobile applications designed for construction supply chain coordination allow site workers and field teams to access, update, and contribute information on the go.

Supply Chain Coordination

Construction projects involve multiple stakeholders, including architects, engineers, contractors, suppliers, and subcontractors. Coordinating and aligning their activities and timelines can be challenging, leading to delays, disruptions, and miscommunication. Technology can play a key role in improving supply chain coordination by facilitating communication, streamlining processes, and enhancing collaboration among stakeholders.

Construction-specific project management software streamlines processes and tasks, enabling stakeholders to plan and schedule activities, track progress, manage resources, and coordinate deliverables, ensuring efficient coordination from start to finish.

Cloud-hosted platforms provide a centralized space for stakeholders to communicate, collaborate, and share and contribute information. By organizing and sharing documents such as drawings, models, permits, and specifications, stakeholders can access the latest information and ensure everyone is working from correct versions.

Mobile applications designed for construction supply chain coordination allow site workers and field teams to access, update, and contribute information on the go. They can submit issues, report progress, present timesheets, capture events, and maintain daily diaries, ensuring real-time visibility and efficient coordination.

Improved communication and collaboration between the office and the field mean that supply chain participants are better able to mitigate risk and make timely and informed data-driven decisions.

It Is Simple to Get Started

In construction, a problem never costs less to fix than on the day you discover it. Addressing supply chain challenges requires collaboration, effective communication, and the adoption of innovative approaches. Off-the-shelf construction technology can streamline project delivery, improve decision-making, and produce better financial outcomes for everyone in the construction supply chain. Construction technology is ready to be discovered and embraced.

Post a comment to this article

Report Abusive Comment