While more construction firms are recognizing the need for construction digitalization and the benefits of digital project delivery, the adoption of BIM and 4D modeling in the heavy civil construction sector seems to be lagging. However, a proven solution that can open doors to newer, more efficient processes is the 4D construction digital twin. As digital twins are becoming more mainstream in the construction industry, they are especially relevant for heavy civil engineers, who are focusing on large complex infrastructure that ranges from transportation works to wastewater treatment plants and earthworks projects. Heavy civil contractors can use digital twins to visualize construction sites and projects in real time from anywhere, helping them make faster decisions, plan more effectively, and mitigate risks for optimal development and delivery of more sustainable infrastructure.

What is a 4D Digital Twin?

At the most basic level, a digital twin is a highly-detailed and accurate virtual representation of a physical asset, project, jobsite, process, or system that enables teams to understand, model, and analyze performance. It creates a single view of the truth, providing all the data necessary to improve collaboration, predict and prevent unscheduled downtime, lower operating costs, and address potential safety concerns throughout the project lifecycle.

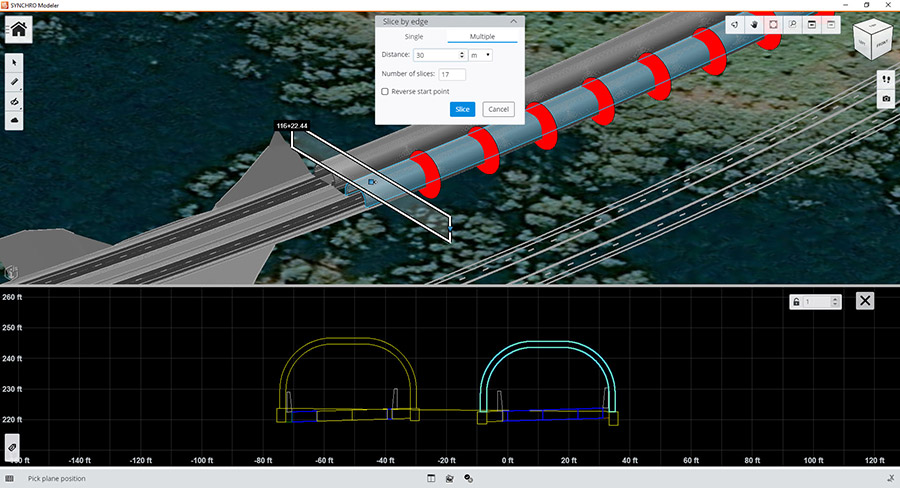

Initially, a digital twin is created by integrating multisourced data from 2D plans, surveys, and drones using reality capture technology and BIM modeling software to create a detailed 3D model that includes layers of metadata, rendered within a collaborative digital workflow. When you add the fourth dimension of time by integrating the project schedule, the 3D model becomes a 4D construction model. Now, the team can analyze and visualize the sequence of events on a digital timeline within the model.

When the 4D model includes information from sensors and Internet of Things technology, providing a live and evolving dataset, it becomes a 4D digital twin. The construction digital twin provides a simulative environment, allowing teams to digitally test construction sequencing and logistics scenarios, verify the as-built situation, or run what-if simulations using live data from building sensors to optimize performance and sustainability.

More and more construction firms have recognized the need for digitization and have begun to realize the significant benefits that digital workflows can bring.

Why Adopt 4D Digital Twins?

The creation and use of 4D construction digital twins is the next step in the evolution of the heavy civil sector to fully embrace construction industry digitalization. As infrastructure projects continue to grow in scale and importance, they also increase in difficulty, creating challenges around resource availability, collaboration, and data transparency. It is imperative for teams to implement the most efficient processes to exchange project data and information. The 4D construction digital twin integrates data from multiple sources and is stored in the cloud, accessible via mobile applications and web browsers, connecting the entire project team in the office and field—from preconstruction planning through to completion.

When mapping out a vast heavy civil construction project, it is often difficult to begin the process of estimating quantities, resources, and accurate schedules. This process has historically been manual, which can lead to mistakes in calculations due to the sheer size of the project site and human error. Implementing 4D BIM construction processes, along with virtual and augmented reality technology, to develop a construction digital twin provides an option for teams to break down large heavy civil projects and tackle planning in smaller sections.

Unforeseen events are also an inevitable challenge during construction. BIM and digital construction workflows can provide teams with the ability to anticipate and identify issues early before working on site. By connecting the construction digital twin to the project schedule, heavy civil teams can run a simulation to determine best-case scenarios for keeping the project on track.

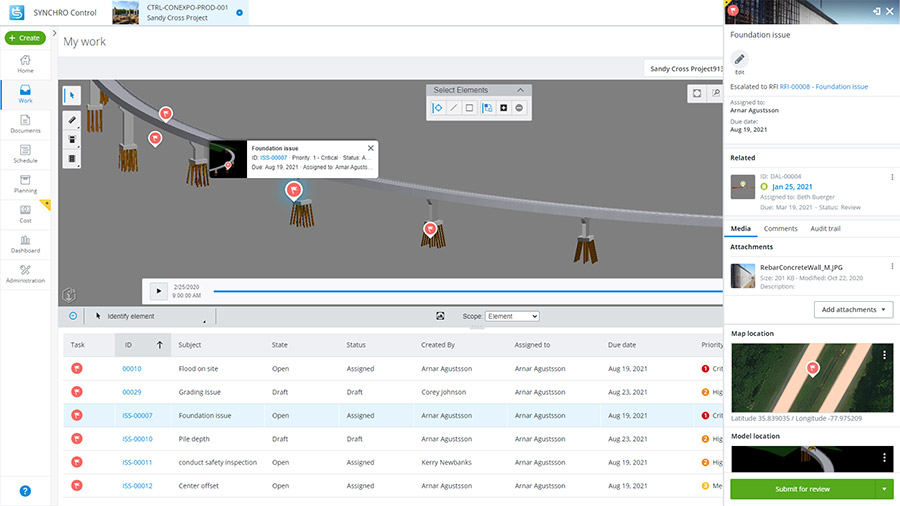

Finally, consistent communication and accurate project documentation is non-negotiable to successful delivery of heavy civil projects. 4D construction digital twins facilitate real-time data sharing within full project context via 4D model views in web, mobile, and desktop applications throughout the entire project lifecycle, ensuring collaboration with the office and field and making better, timely decisions.

Add cost codes and quantity calculations to constructible components, creating faster and more accurate model-based quantity take-offs (QTOs).

Game-changing Industry Benefits

A live construction digital twin transforms workflows—such as resource tracking, inspections, work package planning, and project management—through the 4D BIM construction model context to deliver projects timely and more profitably. Using a 4D construction digital twin, the heavy civil owners and contractors can leverage a single common data environment, split the project model into constructible components, simulate construction sequences prior to building on site, streamline communication and collaboration in real time, and ensure key project outcomes. Working in a live virtual construction environment provides a single source of truth, ensuring clearer project alignment and better decision-making. This instant data sharing capability among heavy civil teams and stakeholders increases productivity, enhances communication, optimizes resources, and provides improved project controls and visibility.

With a 4D construction digital twin, teams can isolate and track specific project elements with automated geolocation features and connect them to the schedule to better assess project progression over time. They can also add cost codes and quantity calculations, creating faster and more accurate quantity take-offs. Knowing exactly where to flag issues and with whom to communicate, while monitoring actual costs versus cost loaded schedules, are game-changing benefits that ensure quicker, data-driven decisions to keep projects on track and within budget.

The industry can use the digital twin to simulate construction to better anticipate and see through key project outcomes, reducing potential risks and errors. Leveraging scheduling and simulations with 4D construction digital twins can reduce costs by 50%, increase field labor productivity by 75%, and reduce overall schedule time by 15%, industrializing delivery of heavy civil construction projects.

Where to Start?

To deliver timely, successful projects and keep everyone connected and on the same page, heavy civil teams need to be empowered with the right 4D digital solutions to simplify and streamline tasks. With a powerful digital construction platform, such as SYNCHRO, the heavy civil industry can unlock the true value of the 4D model and get time on their side as it transforms into a construction digital twin, connected to real-time project data that enables construction teams to work faster, better, and safer.

Post a comment to this article

Report Abusive Comment