"How is this bridge still standing?”

That was the initial reaction of Aaron Stover, Michael Baker International’s vice president and regional bridge practice lead, as he first studied images of a fractured tie beam that forced the May 11 emergency shutdown of the I-40/Hernando de Soto Bridge between Tennessee and Arkansas. Discovered earlier in the day during MBI’s routine above-deck inspection, the fracture on the bridge’s eastbound span affected nearly half the cross-section of a 26-in. by 33-in. welded girder supporting one of the 50-year-old structure’s 900-ft-long, 100-ft-high arched navigation spans across the Mississippi River.

Though component fractures have occurred on older structures, Frank Russo, MBI’s national bridge technical director, says the de Soto Bridge crack was nevertheless puzzling. The tie beam’s .5-in.-thick top flange plate and outer 1-3/8-in.-thick web plate were totally severed, with the fracture extending across nearly half of the bottom flange plate. Additionally, 9 ft of the weld connecting the inside web with the upper flange had separated as well.

.jpg)

Shortly after the fracture was discovered, the 900-ft-long bridge spans were closed and inspections began. Here, workers are taking part in the early stages of phase 2 repair work.

Photo courtesy Michael Baker International

“Usually when something like this breaks, you find it completely broken,” Russo says. “It’s very remarkable that this member didn’t completely fracture.”

Though the fissure’s cause and characteristics remain under investigation, two things were clear as the bridge was immediately closed to traffic—its condition needed to be thoroughly assessed in the event there was additional damage, and a repair strategy needed to be developed as quickly as possible.

The fracture, discovered on May 11, caused an immediate emergency shutdown of the bridge.

Photo courtesy Michael Baker International

Despite the fracture’s extraordinary aspects, there is a strong familiarity among the team tasked with carrying out the assessment, both with the de Soto Bridge and with each other. The Arkansas and Tennessee transportation departments have long shared responsibility for the structure, with ARDOT overseeing inspection and TDOT handling maintenance. MBI, which would lead the response’s aerial inspection and design work, had worked with both agencies, as had HNTB, which performed a full hands-on inspection of the below-deck areas of both tied-arch spans. Experts from the Federal Highway Administration were also involved.

An inspector gets a close-up view of the fracture.

Photo courtesy Michael Baker International

“It’s very remarkable that this member didn’t completely fracture.”

—Frank Russo, National Bridge Technical Director, Michael Baker International

“That gave us a deep bench of structural engineering expertise and resources, allowing for a significant amount of analysis and design to take place in a very short amount of time and with a high level of reliability and accuracy,” says ARDOT spokesman Dave Parker.

The team also had technology on its side, with drone video combining with physical inspections using rope-access techniques to expedite the condition assessment. Drones also allowed the physical inspection of the fracture to be streamed in real time to the office-based design team.

“We could see what the inspector was doing and ask to check out additional aspects, which helped us start planning multiple steps ahead,” says MBI bridge technical director Jason Stith. “It was quite incredible to get that information during a two-hour conference call rather than having to go back and forth over several days.”

This image shows the view when inspectors first discovered the crack.

Photo courtesy Tennessee Dept. of Transportation

The emergency situation for this vital connection between Tennessee and Arkansas required work to progress on a 24/7 basis.

Photo courtesy Kiewit

Multi-path Planning

Though no additional damage was found on the bridge, in-depth inspections indicated that the structural load at the fracture had been shed to the remaining web and flange sections, putting those components under exceptional stress.

“We needed to understand that better before we started yanking around on the bridge, trying to move things back to where they were,” Stover says.

As the team began concurrent design efforts to stabilize the structure and devise a permanent repair, TDOT implemented an emergency construction manager/general contractor procurement that agency commissioner Clay Bright says had the capability “to get involved in the difficult, challenging and at the time, still unknown final repair design.”

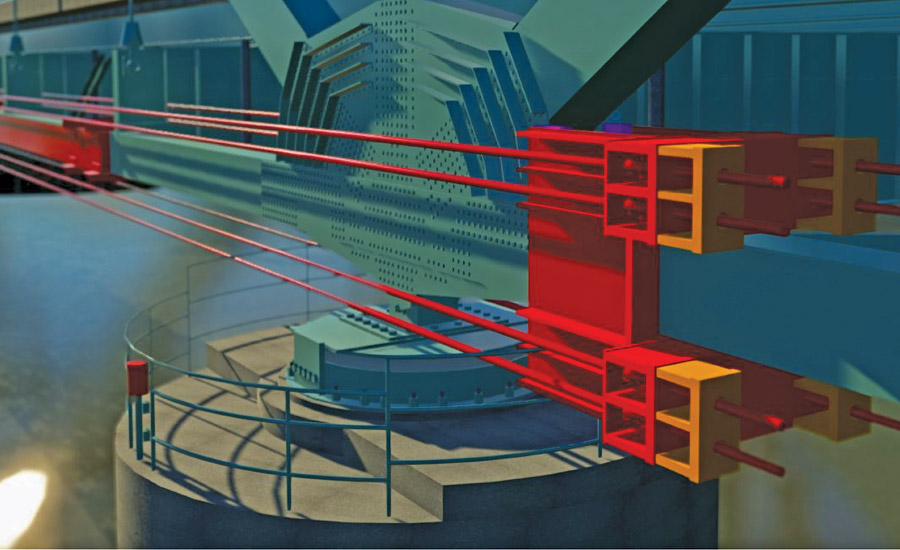

Conceptual rendering of Phase 2 post-tensioning scheme used during the repairs to the structure.

Rendering courtesy Michael Baker International

On the afternoon of May 17, less than two hours after TDOT had selected Kiewit for the project, operations vice president and area manager Chris Frieberg and other firm representatives were discussing stabilization and repair alternatives with the design team.

“We worked through risks associated with different design options and the best way to mitigate them, as well as material availability and fabrication lead time,” Frieberg says. He adds that the solution had to be one the design team could stand behind and his team could build safely.

Rendering courtesy Michael Baker International

“And it had to be permanent, so that the DOTs would be assured of having a safe structure for years to come,” he adds.

The resulting two-phase strategy called for first stabilizing the fracture area with a “splint” of steel plating that would add redundancy to structure. Because the girder was slightly twisted and warped, the plates would be offset to prevent placing any new stress on the area.

While TDOT originally envisioned basing the repair effort from barges, the design team’s loading analysis indicated that the fracture area could be safely accessed from the bridge deck.

“That gave us a more controlled environment for the delicate work we were doing, although we did have to keep personnel and equipment to a minimum,” Frieberg says.

By the end of that first week, Kiewit had assembled a 100-sq-ft suspended platform to install the first of 30,000 lb of HPS70W structural steel plates fabricated on an expedited basis at Stupp Bridge Co. in Bowling Green, Ky.

Over the next four and a half days, crews used chain and air hoists to lift the plates into place, where they were secured with nearly 450 temporary bolts. Frieberg says the work involved some lead paint considerations and confined space protocols when working inside the tie beam but required no additional measures for COVID-19.

The ability to use drones to inspect the damaged bridge aided the project team.

From Stopgap to Structurally Sound

On May 14, just three days after discovery of the fracture, the de Soto bridge was deemed sufficiently stabilized and safe enough for TDOT to reopen the underlying river channel to barge traffic and then transition to the next repair phase. A 150-ft-long section of tie girder encompassing the fracture area would be beefed up with 108,000 lb of additional redundancy plating, with eight 3-in.-dia, high-strength, post-tensioning rods installed alongside the beam to transfer more than 1.2 million lb of tension to the composite section.

The supplemental post-tensioning also allowed workers to remove fractured flange sections for analysis.

“If the entire tie decided to break, which is very unlikely, it has a completely redundant element on the outside that can carry the load,” Russo says.

Frieberg says this strategy required an even higher level of coordination and analysis given that the precision fabrication of specialized post-tensioning components and weldments and additional strengthening plates had to be synced with mobilizing specialty subcontractors and addressing other logistics needs.

“We had three critical paths running simultaneously, and the art of the dance was keeping them all in unison,” he says. “All three converged so that as the design was signed and sealed, material fabrication was underway.”

By July 3, the last of the plates at the fracture location had been bolted into place. But there was still one more important step to complete before the bridge could be declared fully restored. During the initial condition inspection, HNTB conducted non-destructive phased array ultrasonic testing on the tie girders’ 500 welds to determine if similar cracks were forming or could form under certain conditions. Seventeen welds were found to have anomalies, which Kiewit plated over the next three weeks with a total of 78,000 lb of steel to provide additional redundancy. Another 29 weld defects were ground or cored out.

“It had to be permanent so that the DOTs would be assured of having a safe structure for years to come.”

—Chris Frieberg, Operations Vice President, Kiewit

After another round of inspections, the de Soto Bridge’s eastbound lanes were reopened to traffic on July 31, followed two days later by the westbound lanes. That completed an 83-day, 24/7 marathon that was remarkably free of weather interruptions. Costs for the routine and specialized inspections and repairs, currently estimated at $10 million, will be shared by both DOTs.

The effort also concluded what ARDOT’s Parker considers to be a parallel success story—safely shifting the de Soto Bridge’s 40,000 vehicles per day to other crossings, particularly the nearby 72-year-old truss bridge that carries I-55 across the river.

Parker credits the team’s collaborative brainstorming of congestion relief strategies for helping cut the I-55 bridge’s initial hour-long peak-hour backups by more than half and reducing bail-out traffic onto local roads. Both DOTs stepped up services to minimize the effects of lane-closing incidents. TDOT’s Bright notes that motorists’ initial concerns about the safety of the I-55 bridge were alleviated by emergency inspections and the performance of the “robust structure” while the de Soto Bridge was out of service.

“The only issue was a pavement failure in one lane that was quickly addressed during a weekend temporary lane closure,” Bright says, adding that the bridge is currently undergoing its scheduled biannual inspection. “Any new issues will be addressed along with other maintenance work next spring.

Meanwhile, the fractured tie girder section is at Wiss Janney Elstner’s forensic laboratory in Northbrook, Ill., undergoing metallurgic and other tests in an effort to fully understand the factors that led to the fracture. Parker says results of that investigation, scheduled to be delivered by fall, will help the DOTs determine if the structure requires additional attention on top of regularly scheduled inspections and maintenance. A solar-powered strain gauge monitoring system installed prior to the bridge’s reopening also remains operational.

What’s already certain, team members agree, is the essential role team-wide collaboration played in turning a potential catastrophe into a success story.

“If you listened into our daily calls, you wouldn’t have been able to tell who was DOT, who was designer and who was the contractor,” Frieberg says. “Going through the process, we were very well integrated and very open-minded. That was the biggest contributor with coming up with a design solution that could be implemented quickly and safely.”

Questions Remain in Inspection Oversight Controversy

Within hours of the discovery of the de Soto Bridge tie girder, images and video emerged suggesting that the fissure had been months, perhaps even years, in the making despite having been unreported in at least two ARDOT-led annual fracture-critical inspections. Following an internal investigation launched immediately after the closure, ARDOT fired Monty Frazier, a 15-year employee who had led the 2019 and 2020 de Soto Bridge inspections. In addition, the Federal Highway Administration launched an assessment and compliance review of ARDOT’s bridge inspection program, with the results expected by the end of September.

Frazier’s reported assertion that the mobile under-bridge inspection platforms were unsafe to use was countered by the agency’s heavy bridge maintenance staff (HBMS), which, according to an ARDOT interim after-action report, verified that the equipment was stable and provided adequate access to perform hands-on inspection at the fracture location. Nine other fracture structures inspected by Frazier were reexamined and found to be safe.

Frazier has since admitted that missing the fracture was a mistake on his part, but he insists he’s not solely to blame. In an interview with the Daily Memphian newspaper, published on July 22, Frazier said he pointed to the crack’s appearance in photos reputedly dating as far back as 2014 as proof that other inspectors overlooked the condition as well. “If there are that many people who missed the crack over all that time,” Frazier told the reporter, “it’s a problem with the way we inspect the bridge, not just the one guy who happened to be on the paperwork the last time we missed it.”

ARDOT has not verified the validity of the photos and declined to comment on the story. Meanwhile, multiple investigations are underway, including an agency-requested probe by the U.S. Dept. of Transportation’s Office of Inspector General as to whether Frazier’s alleged negligence constitutes a criminal action. A parallel internal investigation by ARDOT’s human resources department is proceeding as well.

In July, ARDOT boosted its historic bridge maintenance system budget by nearly $3 million, providing funding for consultants that will help the agency identify new technologies, improve quality assurance and quality control and improve inspector training.

Post a comment to this article

Report Abusive Comment