Construction crews hit water June 30 while tunneling 600-ft below Southern Nevada's drought-racked Lake Mead to create a third straw. The incident required a hasty evacuation, and could delay project progress by months.

A 200-ft-long by 37-ft-high vault breach caused four days of gradual water seepage that eventually made it no longer accessible. Workers were building a 28-ft-dia, 100-ft-long horseshoe-shaped starter tunnel before using a $25 million Herrenknecht 1,500-ton tunnel boring machine when the incident occurred.

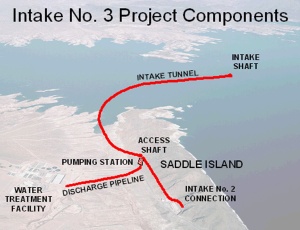

Vegas Tunnel Constructors LLC � a joint-venture of S.A. Healy Co., Lombard, Ill. and Impreglio S.p.A., Sesto San Giovanni, Italy � won the $447-million design-build contract in March 2008 to build a 24-ft-dia, 3-mile intake tunnel beneath Lake Mead that will draw water deeper than its counterparts in case drought conditions persist. A 115-ft drop in water level since 2000 has left the lake half full.

�We always know in underground construction there are some unexpected risks and certain conditions,� says Marc Jenson, Southern Nevada Water Authority�s engineering director. �We are working together to remedy the situation. We have no expectation that this devastating to the project. This is just a minor setback.�

The flooded cavern was brought under control by two portable pumps that removed up to 400 gallons per minute. No one was injured; some excavation equipment, however, was left behind underwater. Underground TBM assembly had yet to occur.

On July 12, Spokane, Wa.-based subcontractor Crux Subsurface Inc. started drilling north of the 32-ft-dia., 600-ft-deep access shaft along Saddle Island's western shore line. The firm will locate and reinforce voids in the rock with grout to stabilize geotechnical conditions. Water will then be pumped-out, clearing the cavern, so TBM staging and assembly can commence; the cavern will become a forebay upon completion.

The project, SNWA�s largest to date, had a 1,571-day schedule and expected finish date of July 2012. It's too early to determine the delay length and repair cost, and SNWA has yet to rule on the accident.

�There are contingency measures built into the schedule that identify areas for adjustment for different conditions,� says Jensen. �We have a change order allowance.�

Post a comment to this article

Report Abusive Comment