A $680 million phase of the massive, 13-year expansion of the Newtown Creek Water Pollution Plant in Greenpoint, Brooklyn was completed in February, increasing the plant capacity by 50 percent and improved wastewater treatment processing.

Newtown Creek is the largest of New York City’s 14 wastewater treatment plants serving over 1 million residents. Constructed in 1967, the plant was designed to treat 310 million gallons per day (mgd). The expansion, begun in 1998, will expand plant capacity to 700 mgd and bring Newtown Creek into com-pliance with the Federal Clean Water Act.

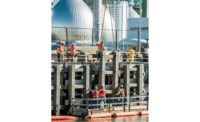

This project phase, which began in August 2003, encompassed reconstruction of four existing aeration/sedimentation tanks in the Central Battery and construction of new North Battery treatment tanks, including four grit/aeration tanks and eight sedimentation tanks. A 40,000-sq-ft North Control Building was built to house process equipment for the new North Battery and reconstructed Central Battery. A new influent distribution system and new process air system were also installed.

The first step in this phase constructed the new treatment tanks and processing equipment, with a capacity of 150 mgd, on a site adjacent to the plant.

Complications at the site included the water table just 12-ft below grade and soil contaminated from prior industrial uses. A metal sheeting system was driven into the ground around the site to support excavations and cutoff water infiltration.

The excavation site was then divided into 50-ft. square grids, 5-ft. deep. Each grid was tested for contaminates to determine appropriate disposal methods. Deep excavation, sometime 30-40-ft. below the water table, removed 250,000-cubic-yards of soil.

To reconstruct the existing treatment tanks, the team had to divert sewage flows to the newly completed North Battery facilities without interrupting plant operations.

Sewage from Manhattan flows to the plant through a tunnel under the East River. A 10-ft diameter shaft rising 350-ft transports the sewage from the tunnel into the plant. The first diversion required cutting an 8-ft diameter core into the shaft without dropping the cut plug down the shaft.

A custom drilling rig was design with so that the operations were above the water and the drilling mechanism underwater. A tall shaft built above the existing structure was filled with water to equalize the pressure inside the existing force main during drilling.

The second diversion drilled 60-in horizontal cores into a live force main using the custom drilling rig. The main, a 16-ft by 10-ft rectangular tunnel, transports sewage from Brooklyn and Queens.

Key Players

Owner: New York City Department of Environmental Protection

General Contractor: Skanska USA Civil Northeast Inc., Whitestone, N.Y., in a joint venture with Picone/McCullagh JV and Perini Corporation, Peekskill, N.Y.

Engineers: Joint Venture of Greeley & Hansen, New York, Hazen & Sawyer, New York and Malcolm Pirnie, White Plains, N.Y.

Masonry Subcontractor: Navillus Contracting, Queens, N.Y.

Sludge Collection Equipment: E-Mech Contracting, Wyandanch, N.Y.

Process Air Piping: Heritage Mechanical, Deer Park, N.Y.

Painting: L & L Painting, Hicksville, N.Y.

Trucking and Disposal: Leticia Inc., Hillside, N.J.

Instrumentation and Control Wiring: Five Star Electric, Ozone Park, N.Y.

Post a comment to this article

Report Abusive Comment