The late Detroit Red Wings hockey great Gordie Howe was beloved in his native Canada and in his adopted U.S. home. A new international bridge connecting both places is trying to create similar goodwill for border traffic, but the project’s public-private partnership team and the Canadian government authority it is working for will have to join together to shift lines and mount a comeback in the third period of its construction.

The $4.5-billion Gordie Howe International Bridge is planned to connect Detroit and Windsor, Ontario, by the end of 2024 with six lanes of traffic. Having no overhead structure, it will relieve the limits on the height of trucks that use the current options at the busiest commercial border crossing between the U.S. and Canada—the Ambassador Bridge and the Detroit-Windsor tunnel.

When it reaches its planned length of 1.5 miles, it will become the longest cable-stayed bridge in North America, twice as long as the Verrazzano-Narrows Bridge that connects Staten Island to Brooklyn, and the fifth-longest in the world. Two 722-ft-tall, inverted Y-shaped towers, one in the U.S. and one in Canada, will support the bridge. The span has a continuous curve, anchored at each end by the towers that suspend the bridge deck with cables. The U.S. section’s side span is 1,171 ft and the Canadian section’s side span is 1,155 ft. Both are supported by 27 backstay cables, and they each have three pairs of ancillary piers that transfer loads directly to the ground. The piers will support curving access ramps that swing up from the ground to support the bridge deck.

“It really was like trying to thread a needle,” says Laura Aylsworth-Bonzelet, an AECOM vice president on the design team in the Traverse City office. “It had to avoid outlines identified as where the bad conditions on the ground were, plus there were concerns with shipping. They wanted to keep the river open during construction as much as possible and that meant no pier construction in the water.”

PROJECT FACTS

- Cable-stayed bridge design

- Six lanes: three Canadian-bound, three U.S.-bound

- Total length: 1.5 miles

- Main towers will be approximately 750 ft high

- Dedicated multi-use path 3.6 miles wide to accommodate pedestrians and cyclists

CANADIAN PORT OF ENTRY

- Site: 130 acres

- 133,881 sq ft of building space

- Inbound border inspection facilities for both passenger and commercial vehicles

- Outbound inspection facilities

- Toll collection facilities for both U.S.-bound and Canada-bound traffic

U.S. PORT OF ENTRY

- Site: 167 acres, 350,454 sq ft of building space

- Inbound border inspection facilities for both passenger and commercial vehicles

- Outbound inspection facilities

- Commercial exit control booths

MICHIGAN INTERCHANGE

- 1.8-mile section of Interstate 75, local road improvements, five new roadway and pedestrian bridges crossing the highway, will link I-75 with Highway 401 in Windsor

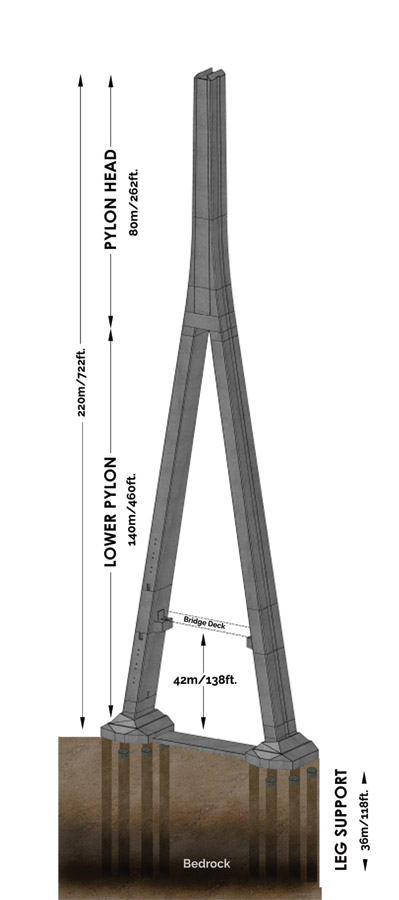

Each bridge tower is made of cast-in-place reinforced concrete built in a sequential manner through lifts approximately 15.3 ft tall to achieve their aesthetic design and desired functionality. The tower legs are 460 ft tall and will

hold the pylon heads that suspend the bridge.

Photo by Jeff Yoders/ENR, Model and graphic courtesy of Windsor-Detroit Bridge Authority

P3 Delivery and Operation

The Bridging North America (BNA) Constructors Canada GP team won the design-build-finance-operate-maintain contract in 2018 from the Windsor-Detroit Bridge Authority (WDBA)—the Canadian Crown corporation created to deliver it. The P3 consortium includes ACS Infrastructure, Dragados Canada, Fluor and Aecon. The full scope of the project includes four separate segments: the bridge itself, the port of entry in Canada, the port of entry in the U.S. and the Michigan Interchange that will link the bridge to Interstate 75. The Canadian port of entry work also includes the toll plaza.

The Michigan Dept. of Transportation will take over maintenance and management of the Michigan Interchange when the bridge is completed, and BNA will begin a 30-year operation-and-maintenance contract for the rest of the project, excluding the ports of entry, which will be operated by U.S. Customs and Border Protection and the Canada Border Services Agency.

Crews are now working on the 262-ft-tall upper pylon of the Canadian side’s tower, placing and tying the

rebar cages that will strengthen concrete as they step up the tower

Photo courtesy of Bridging North America and the Windsor-Detroit Bridge Authority

Under the deal agreed to by former Michigan Gov. Rick Snyder (R) and former Canadian Prime Minister Stephen Harper (C) in 2012, Canada will charge tolls to reimburse its government for project costs, the Michigan Interchange and the cost of required land acquisitions in both countries.

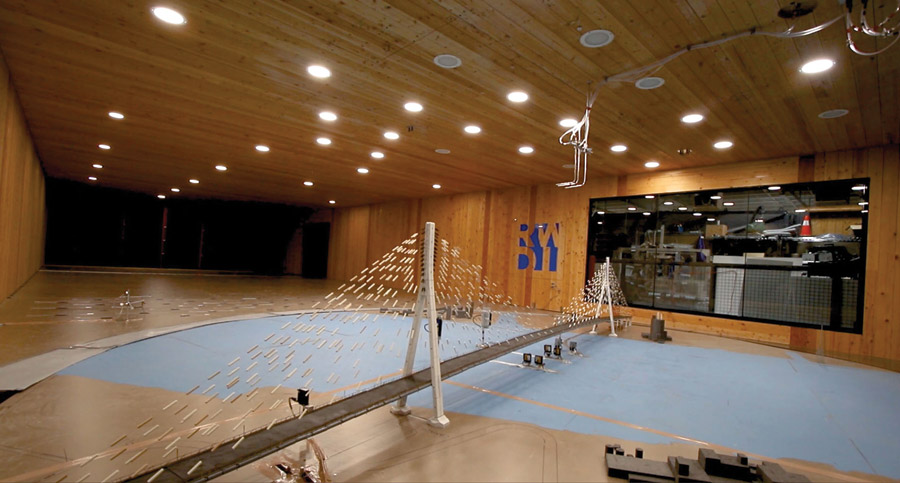

After being selected in late 2018, AECOM deployed separate U.S. and Canada design teams on the project due to different building standards on either side of the river, but WDBA still wanted common themes, including aesthetics. AECOM used its building information modeling (BIM) capabilities for roadway, terrain, utility and sewer network design and analysis, and also incorporated environmental, water and geotechnical datasets into the plan. AECOM designed alternative alignments and drainage schematics for the I-75 interchange to determine the optimal proposal.

Crews bend and build rebar cages that are lifted to the top of the U.S. Tower while simultaneously working on cross beams and corbels in preparation for bridge section placements on the Canadian side.

Photo courtesy of Bridging North America and the Windsor-Detroit Bridge Authority

COVID-19 Complications

When the pandemic hit in 2020, AECOM design teams relocated to over 800 home offices. Since they were already working within Bentley’s ProjectWise cloud environment, all members of the Michigan Interchange design team continued to collaborate with each other and with the overall project team.

Construction, however, was a different story. Sitework included the installation of more than 250,000 wick drains in the ground planned for both ports of entry, relocation of utilities and the construction of new pier caissons on both sides of the river. A railroad track also had to be rerouted, significantly impacting the erection sequence of the U.S. tower.

Michigan Gov. Gretchen Whitmer (D) had exempted the project from her state’s initial stay-at-home order that had shut down construction elsewhere between March and May 2020, defining both the bridge and the Michigan Interchange as “essential.”

Piles are driven on the U.S. side.

Photo courtesy of Bridging North America and the Windsor-Detroit Bridge Authority

But following COVID-19 guidelines meant some impacts couldn’t be helped. Contact tracing was key to preventing anyone from getting the virus onsite for the entirety of 2020 and 2021. However, when any one worker got it, that whole crew quarantined under the protocol, which slowed work down.

“We’ve not changed the schedule, but we’re trying to make up time from COVID impacts and everything else,” says Michael Hatchell, CEO of BNA.

In February, protestors sympathetic to the Canadian trucking demonstration in Ottawa blocked the Ambassador Bridge, making the argument for just how necessary another area bridge border crossing really was. Automakers on both sides of the border reported $300 million in operational losses due to the shutdown.

Two ports of entry with secure warehouse and inspection facilities are part of the project. The Canadian port of entry (above) is enclosed while the U.S. one (below) is still placing tilt-up concrete sections.

Photos courtesy of Bridging North America and the Windsor-Detroit Bridge Authority

Final Tower Work

The legs of both towers are complete and the rebar cages at their tops were being prepared for concrete placement of the 262-ft-tall pylon heads as of late June. Each Y-shaped bridge tower is made of cast-in-place reinforced concrete and built in sequence through lifts of approximately 15.3 ft. Corbels on the legs will allow bridge deck sections to be attached to them in the next phase of construction. On the Canadian side, work has already begun to start installing the corbels, which will each contain 60 tons of stainless steel rebar, post-tensioning bars and concrete.

Concrete work on the upper pylons continues, with jump form systems used to construct the 262-ft-tall pylon heads that will merge the tower legs into a single structure. The lower pylons are the longest portion of the bridge towers; each is composed of 29 different segments. Each segment has an average height of 15.3 ft and requires 128 cu yd of concrete and 121,254 lb of rebar.

Once the transition work is complete, construction will begin on the pylon heads, which measure about 262 ft tall each. Critical to the cable-stayed design, anchor boxes within the pylon head will house 216 parallel strand stay cables that will connect the towers to the bridge and decks.

Each tower is supported by twelve shafts drilled 118 ft into bedrock, capable of carrying a similar load to a 12-story office or residential building. The shafts were filled with 69,000 gallons of concrete and are connected by 5,250 ft of post-tensioning cables to create firm footings. Each tower is planned to weigh 66 million lb when completed. The bridge towers and cable system are being constructed to support nearly 34 million lb of weight that comes in the form of cars, trucks and other traffic crossing the border.

The project’s tower cranes, one for each tower, have a horizontal jib that can reach 197 ft and have a maximum load capacity of 110,000 lb.

Work on cross beams in both towers will continue through the end of the year, too, Hatchell says. Construction of the anchor boxes within the pylon heads is on track to be completed this year, as are the housings for the cables connecting the tops of the towers to the bridge deck. Plans for delivering the bridge sections haven’t been finalized yet.

As with many recent projects, materials supplies have been affected, although superintendents say that acquiring equipment and major materials such as steel before the pandemic helped mitigate supply-chain issues.

“Some of the lighting has been a challenge,” Hatchell says. “Ladders, gates and pretty much all of the aluminum extrusion-type things you have to build. That’s been difficult. There’s been a supply issue with it. It hasn’t impacted a whole lot yet, but it’s been difficult to get.”

The nature of the terrain, heavily mined for salt through the 20th century, dictated the Gordie Howe Bridge’s alignment and the placement of towers on both shores.

Rendering courtesy of Bridging North America and the Windsor-Detroit Bridge Authority

Note to Lenders

In March, S&P Global reported in an investors’ note that BNA was reporting a potential eight-month COVID-19-related delay, an increase from a previously noted four-month delay, pushing its substantial completion date to November 2024.

BNA has started implementing work acceleration measures while waiting for approval of a new schedule agreed to by WDBA. In the absence of successful acceleration and mitigation measures, an additional, newly reported 245-day delay on the bridge component could eat up the entire cushion that the bridge schedule had between substantial completion date and bridge handover date, potentially causing a further eight-month delay to the substantial completion date.

The report cited delays in structural delivery and subsequent knock-on effects that could push temperature-sensitive pavement work into the inhospitable winter months. A 2021 S&P note said that BNA had submitted multiple supervening event notices to WDBA for schedule relief, cost compensation or both and that the two parties were working collaboratively to resolve the issues. Both notes did, however, say that with more than two years left to complete the project, accelerating work and resequencing activities could succeed in making up for lost time.

While the underground work of the Canadian port of entry is substantially complete, the U.S. side still hasn’t completely finished its customs and warehouse facilities. Both are moving forward with the construction of the buildings and the canopies. The Michigan Interchange activities are being constructed along a 1.8-mile section of I-75 stretching from west of Springwells Street to east of Clark Street, and appeared to be making progress toward on-time completion when ENR was there in June.

“We’ve looked at the number of crews we’re trying to use and doubling them to make up cycles on the bridge,” Hatchell says. “We brought in teams from Toronto to get help with the bridge, just to add another team working.”

Post a comment to this article

Report Abusive Comment