Owner: Chicago Dept. of Transportation

Lead Design Firm/Civil Engineer: AECOM

General Contractor: F.H. Paschen

Structural Engineer: AECOM

Structural Engineer (Approaches): HBM Engineering Group

Construction Engineer: TranSystems

Steel Fabricator: Hillsdale Fabricators

Steel Bending Specialist: BendTec

Steel Erector: S&J Construction

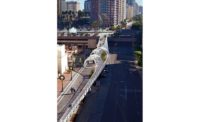

The 41st Street Pedestrian Arch Bridge project team overcame the daunting task of spanning 1,470 ft over active rail lines, catenary wires and all eight lanes of Chicago’s Lake Shore Drive. The $28-million pedestrian and bicycle bridge features twisting approaches that form a giant S connecting the Park Crescent community in the Bronzeville neighborhood to 41st Street Beach.

The safe passage over the roadway and railway has become a functional work of engineering art, according to this year’s project judges. The 240-ft-long inclined, fabricated steel arches holding up the bridge are just as stunning as the approaches, they add.

The primary obstacle—Lake Shore Drive—runs nearly 16 miles like an asphalt and concrete ribbon separating Chicago from a series of public parks, beaches and other amenities east of it. On the city’s South Side, the Metra commuter and Canadian National (CN) railroad lines run parallel to LSD, complicating locals’ efforts to enjoy the public assets that Chicago’s 19th-century urban planner Daniel Burnham had the foresight to include in his original plan of Chicago as land reserved for public use in perpetuity. Of the few existing bridges on the South Side, most were not wheelchair accessible and ADA compliant. In 2003, then-Mayor Richard M. Daley held an international design competition to try to connect the South Side to its parks.

“The bridge design competition was based off the South Lakefront Study, which looked at access to the lakefront compared to North Lake Shore Drive,” says Tanera Adams, a civil engineer in the Chicago Dept. of Transportation. “There was a connection to the lakefront [on the North Side] every quarter mile, whereas, on the south side, there were not quite as many connections. You could see [the lakefront], but you couldn’t get to it. You’d have to travel quite a few blocks. For the 41st Street bridge location, there was no bridge there at all at the time.”

One of the entrants in that competition—the team of AECOM and Cordogan, Clark & Associates (CCA)—came up with the idea of using serpentine approaches and twin arches. Unlike typical arch bridges, which are symmetric in horizontal and vertical directions, the team’s design called for spans on reverse curvature and on a long crest curve where the center between the arches is 7 ft higher than the outside ends of the arch at the approaches. The arches incline at 30˚ from vertical, and the deck rib curves on a 400-ft radius, supported by hangers on one side only.

What ultimately was built “really originated from that design competition, because they were looking for some smooth curves,” says Mike Eichten, vice president for central division transportation at AECOM. “It was really an aesthetic approach to it. It was all about the end user and a great experience whether that was bikes or pedestrians.”

The design competition resulted in five winners for five new bridges, including the AECOM/CCA team, chosen from among 67 entrants by a jury of experts.

Years would pass, however, before funding was lined up. Chicago finally received an $18.76-million Transportation Investment Generating Economic Recovery (TIGER) grant in 2014, and that’s when AECOM refined the details of how such a bridge could be built and moved the project forward as the lead design engineer. The rest of the money for the project eventually came from the Chicago and Illinois departments of transportation. A notice to proceed followed that year. TranSystems joined the team as the construction engineer, and F.H. Paschen was hired as the contractor. By June 2017, construction was ready to begin. Immediately, the team had to coordinate work with the various community stakeholders.

“It was a good example of an all-in approach” and coordination between the alderman, residents, subcontractors, CN, Metra and the departments of transportation, Eichten says. “It seemed like everybody was really all in and there was big buy-in right from the start.”

Temporary Bridge Scheme

The serpentine approaches were necessary, particularly on the western side, to facilitate a 5% grade ADA ramp and still squeeze the approach within a footprint that got it over the catenary electrical lines and their towers. The vocal Chicago cycling community also reacted positively to the longer approaches rather than ramps with setbacks or other options that would force riders to dismount to cross Lake Shore Drive.

The 35th Street Bridge north of the project, which had begun construction two years earlier, saw its share of delays trying to work around the active Metra and CN rail lines and having to cross 75 ft over Lake Shore Drive.

During the 41st Street Bridge planning stage, Paschen, AECOM and TranSystems talked over the idea of using a temporary bridge during construction with their client, the Chicago Dept. of Transportation. All agreed that it was the way to go.

“It was the best solution to have as minimal an impact on the railroads as possible,” says Tim Bea, Paschen’s senior project manager. “Between the four commuter Metra lines and the two CN railroad tracks that we went over, there are six lines in all. You could have shored the structure, but obviously you would’ve had to run post shores and shoring in between the tracks. It would have been a mess.”

TranSystems project engineer Brian Racine says building the temporary structure was well worth the expense.

“We weighed the pros and cons of a temporary bridge or other erection methods, and putting in this temporary bridge was well worth the money to provide a safe platform for our workers,” he says, “but also to provide protection for the railroads and to eliminate the need to have the track shut down. So, after that, we had to design the new bridge a little higher over the catenary wires so we could squeeze in this temporary bridge. It was really a unique opportunity.”

Thanks to Paschen’s robust prefabrication plan and a quality-control program modeled after that of the U.S. Army Corps of Engineers, the project’s substructure elements were completed by November 2017, just five months after groundbreaking. 3D Tekla and Revit models were used to assist the fabricators and steel erectors in both placement and fabrication of the steel tubes of the arches and deck sections. Stringent requirements were put in place to ensure the curved steel tubes maintained their round shape and precise geometry from fabrication to field.

To provide structural stability, part of the bridge’s design called for kicker ribs to be introduced at each end of the arch span in a basket handle configuration to provide lateral support to the main arch rib. Many of the structural challenges involved the connection details, including the box beam connection to the round deck ribs, a hold-down device to combat large uplift and torsional forces, hanger and arch base connections, and expansion bearings with large lateral resistance and lateral stop and jacking supports.

Paschen used LiDAR laser scanning of the foundations, which were then replicated at Hillsdale Fabricators’ St. Louis shop to meet the quarter-inch tolerances necessary for proper installation.

“We held weekly meetings from the time steel drawings were released,” says Bea. “We got the two main fabricators together. We set that tone as a team to hold each other accountable. That was an important part of delivering on time.”

Prior to shipping, the large sections of the bridge were assembled at Hillsdale’s shop for quality control. Paschen’s ability to procure 1.2 million lb of structural steel and large diameter steel pipe and accurately fabricate it through Hillsdale and bending fabricator BendTec, all in an accelerated time frame, allowed the bridge to be constructed under budget and opened to the public six months earlier than the contract completion date of April 2019.

Community Reaction

The response from the community for the 41st Street Pedestrian Arch Bridge has been unprecedented for a Chicago pedestrian and bicycle bridge.

“People say to me, ‘Oh, the big blue bridge. That’s awesome,’ ” Eichten says. “It has such a unique aesthetic to it, but it is, as we mentioned before, just a pleasure to use.”

Bronzeville residents even put signs up thanking the contractors and the city for the bridge that connects them to their lakefront.

“I’m very proud of that structure,” says Adams, a Chicago Dept. of Transportation civil engineer. “It’s been a labor of love since the design competition. It’s been a long time coming, and it’s very rewarding to see it being built and to actually see people using it. It’s an asset to the community and to the lakefront.”

Post a comment to this article

Report Abusive Comment