Why was Jim O’Brien so successful in promoting the concept of critical path management in the 1960s, and yet today many contractors would prefer to revert to bar charts? The bar chart – or Gantt Chart – was invented in 1910 as a vast improvement over prior art of making a to-do list and perhaps reordering roughly in a preferred sequence. It allowed users to create a true “schedule” of tasks or “activities” including estimated duration, preferred (usually early) start and finish dates. The placement of activities to specific dates was accomplished by the intuition of a superintendent alone or with his or her team and they figured out how the finish of one activity may impact the start of another.

Done properly for any but the simplest of projects, it required significant effort. But this consideration of logic was rarely recorded.

If even minor changes were made to the scope, or actual durations and progress did not match those initially anticipated, the team was required to meet again to re-create (or using today’s jargon, “rebaseline”) the bar-chart schedule, often requiring more than 40% of the initial effort.

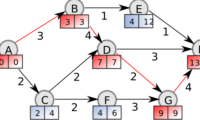

Jim Kelly and Morgan Walker developed the mathematics in 1956, and with John Mauchly (who designed the first general purpose electronic digital computer) created a means to record the logic discussed by the team and automate the calculation of early dates. These dates represent the earliest that an activity may be anticipated to start and finish (based on logic and durations) and leaves it to the superintendent to prosecute some and defer others based upon available resources. As an added benefit, the computer also calculated late dates, representing the latest start and finish necessary to complete the project by a specified date or as early as possible.

Review of both early and late dates now assist the superintendent to deploy resources and to determine which activities to perform as soon as possible and which to allow to “float” toward the “drop dead” deadlines set by the calculated late dates. Thus, performance of some activities must start and finish as soon as possible and are deemed “critical” to timely project completion, while others may “float” to achieve the best deployment of resources subject to the primary goal of timely completion. Initially called the “Kelly-Walker Method,” this procedure was rebranded as the “Critical Path Method” or CPM and sold to the world by Jim O’Brien’s book, CPM in Construction Management (1964: McGraw-Hill.) Notice well the primary goal of the contractor and its superintendent: to complete on-time or even earlier if possible.

Unlike the world of manufacturing, construction usually permits the contractor to bring in additional resources as needed, to use or hold in reserve, release and then if necessary to bring back, without regard for “best use of the resource,” and all to support this primary goal. And both the mathematics and initial computer instruction programs were specifically developed to support this primary goal.

What happened to reduce enthusiasm for use of CPM?

This is why Jim O’Brien and others were so successful in selling this new concept to contractors.

Despite the extra work of asking “why must A be done before B” and recording this logic in a strange format to be entered into a computer, the benefits of assisting in building the preferred schedule, and in rapid recalculation as actual diverged from anticipated, sold the concept. Contractors rushed to implement this new idea without demands of owners – this was scheduling of, by and for the contractor. CPM in Construction Management became (and remains) the single best seller of McGraw Hill's professional series.

What happened to reduce enthusiasm for use of CPM? In United States v. Citizens and Southern National Bank, 367 F. 2d 473 (1966), both subcontractor and contractor were able to show delay damages caused by factors for which they were not responsible. In the absence of clear evidence separating the two claims, the court rejected both claims, stating, “As the evidence does not provide any reasonable basis for allocating the additional costs among those contributing factors, we conclude that the entire claim should have been rejected.” But that changed with the advent of CPM. As early as 1963–1964, consultants to the litigants on both sides of a case involving the Atomic Energy Commission used CPM to prepare their positions. And by 1967 other courts were citing CPM as the basis for decisions.

Separation of Competing Claims

By 1972, courts were demanding a CPM schedule be used as the basis for allegations of delays to allow separation of competing claims, as in (Appeal of Minmar Builders, Inc., GSBCA No. 3430, 72-2 BOA.) With CPM now available to be used as a weapon, rather than as a tool, the first effort to alter its primary purpose began. The mathematics of 1956 and software developed to support CPM had always been understood to have tolerances and be approximate. But in the courtroom, the printouts and exhibits prepared by “experts” provided only “the computer says so and thus it must be.” Software that permitted a party to bend the calculation to a desired result was desired, and provided by willing vendors. Options that may be proper in only rare circumstances were added – and not reported as used by the printouts.

And only now did owners (to their contractors – or contractors to their subcontractors) begin to require a CPM of their subordinate, and with the purpose to “game the claim” rather than “provide additional assurance that the subordinate can complete on time.” As owners demand the CPM and specify software to be used, so the developer of the software has a new voice dictating new features. The software is no longer of, by and for the contractor.

Concurrently, others outside of construction viewed the “computer-drawn bar chart” and desired the same for their business use neither knowing, understanding nor caring that CPM calculates two schedules (early and late) from which the team leader (or superintendent) is advised how to deploy resources for a working schedule. An alternate algorithm based on best (usually continuous) use of fixed resources (whether machines of iron or computer coding personnel chained to their cubicle) was incorporated, perhaps even knowing that would delay the project, but for a possibly lower cost.

Modified Software

At this point the major software developers had to choose where to place programming resources – to serve 35,000 construction customers buying 350,000 licenses or to serve 5,000 IT customers buying 1 million licenses. Meeting with 5,000 decision makers who each may buy thousands of licenses is a lot easier and a lot more productive for sales. The software companies modified their product to add features for the 5,000. Top management of the 5,000 did not want irrelevant and “confusing” options, and so the original algorithms of 1956 were removed.

Owners specifying CPM for construction did not care that software may not assist a contractor so long as it may hamper claims. Contractors finding software did not assist earliest completion now provide minimal effort to prepare the submittal required for payment, while falling back to simpler tools to actually manage the project. And so today many contractors have reverted to bar charts and other tools to display their preferred (if not most likely to bring in the project on-time) schedule.

The mantra of manufacturing, best productivity of the unit or activity or of the individual, has eclipsed attempts to achieve the best (or fastest) project and the very concept of team effort. So our challenge is to again teach construction contractors and others desiring earliest completion of projects, from the superintendents in the field to the professional managers in the boardrooms, that the mathematics and discipline of CPM, coupled with proper software to solve this problem and not those of others, will deliver return on the intellectual effort required.

I think Jim would agree this may be more difficult today than in the early 1960s.

Post a comment to this article

Report Abusive Comment