New photos show big cracks, but, so far, tests suggest no definitive cause of last March's tragic bridge collapse in Florida.

The photos from the National Transportation Safety Board show in more detail the cracks that contractors and engineers were attempting to remedy at the Florida International University pedestrian bridge, whose sudden, catastrophic collapse on March 15 killed six. But initial testing of bridge components fails to point to a smoking gun, according to the NTSB.

FHWA's Turner-Fairbank Highway Research Center evaluated one of the steel post-tensioning rods from diagonal member 11 involved in the re-tensioning activity that took place on March 15.

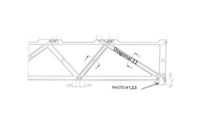

Released Aug. 9 as part of an investigation update, the photos show cracking in vertical member 12 as well as diagonal member 11, which has been a focus of investigators. Diagonal member 11 is located at the structure's north end, where the collapse appears to have started. In May, a preliminary NTSB report had stated the agency was studying "the propagation of cracks" near diagonal member 11. Crews reportedly had been re-tensioning diagonal member 11 at the time of the collapse.

For the update report, the Federal Highway Administration's Turner-Fairbank Highway Research Center evaluated one of the steel post-tensioning rods from diagonal member 11 involved in the re-tensioning activity March 15 and the hydraulic jack that was used.

The Aug. 9 report described the testing procedure:

"A tension test to failure was conducted on one of the 1¾-inch-diameter post-tensioning rods removed from diagonal member 11 to check the rod's conformance to ASTM International A722. Standard round-bar tension-testing specimens were sampled from the 1¾-inch diameter post tensioning rod removed from diagonal member 11 and from an exemplar 1¾-inch diameter tensioning rod obtained from the collapse site. The specimens were tested in accordance with ASTM A370."

Additionally, "Rockwell C hardness measurements were performed on a cross-section of the 1¾-inch diameter post-tensioning rod taken from diagonal member 11 and on a cross section of the previously mentioned exemplar 1¾-inch diameter tensioning rod obtained from the collapse site."

|

| An image of a crack along the bridge's diagonal member 11. |

The NTSB added: "The initial results from these tests and examinations have, thus far, not indicated any notable material issues."

Investigators also examined a roughly 5-ft-wide section of bridge deck, located near nodes 11 and 12, evaluating the size and location of its reinforcement bars to determine if they were in accordance with design plans.

Here, too, the items appeared to be as designed, the NTSB stated: "The preliminary evaluation of the saw-cut surfaces that were internal to the bridge deck and diaphragm II revealed sound concrete in the undamaged surface areas and embedded reinforcing steel consistent with the reinforcing prescribed in the final design plans."

The photos included in the NTSB's latest update illustrate why the agency is focused on these sections of the bridge structure. Photos released earlier in the year showed cracking of the 174-ft-long bridge structure prior to it being moved from the casting yard, where it was fully assembled. On March 10, crews with Barnhart Crane & Rigging transported the span and set into place atop permanent bridge piers located on SW 8th Street.

The latest photos of members 11 and 12 were taken on March 13, just two days prior to the bridge structure collapsing. The photos were provided by Munilla Construction Management and Bolton, Perez & Associates Consulting Engineers. MCM was partnered with FIGG Bridge Engineers, the bridge's engineer of record, as co-leaders of the project. FIU was the project owner.

|

| An image of a crack on the deck of the bridge adjacent to vertical member No. 12. |

According to the Florida Dept. of Transportation, March 13 was the same day that FIGG engineer W. Denney Pate left a voicemail with the state agency addressing the cracking issue. FDOT was not officially a member of the project team.

FDOT's transcript of Pate's voicemail read: "Hey Tom, this is Denney Pate with FIGG Bridge Engineers. Calling to … share with you some information about the FIU pedestrian bridge and some cracking that's been observed on the north end of the span, the pylon end of that span we moved this weekend. … We've taken a look at it and, obviously some repairs or whatever will have to be done, but from a safety perspective we don't see that there's any issue there so we're not concerned about it from that perspective, although obviously the cracking is not good and something's going to have to be … done to repair that. At any rate, I wanted to chat with you about that because I suspect at some point that's gonna get to your desk."

On the morning of March 15—the day of the collapse—project team members held a two-hour meeting focused on the cracking issue. According to a March 17 statement from FIU: "The design-build team of MCM and FIGG convened a meeting … to discuss a crack that appeared on the structure. The FIGG engineer of record [Pate] delivered a technical presentation regarding the crack and concluded that there were no safety concerns and the crack did not compromise the structural integrity of the bridge."

One reader responding to ENR's posting of these photos was William L. Gamble, professor emeritus of civil and environmental engineering at the University of Illinois in Urbana. In comments sent to ENR, Gamble noted: "After even a brief look at these pictures, I am astonished that anyone who had ever taken a course on reinforced concrete could have dismissed them as anything other than deadly serious. If such cracks had been seen in an occupied building, the correct response would be to pull the fire alarm and tell every one: 'Run, don't walk, to the nearest exit.'"

In the case of this pedestrian bridge project, Gamble asserts that responsible parties should have taken steps to "close everything near and under it until it had been either significantly shored up or demolished. I taught courses on reinforced and prestressed concrete for 40 years, and am appalled at the response, or lack thereof, in this case."

The NTSB has not yet determined a probable cause. A final report is not likely until 2019, or possibly 2020, according to the board.

Post a comment to this article

Report Abusive Comment