For the second time in six months, an unexpected intrusion of water and mud has stalled the $447-million construction of a third water intake at Lake Mead near Hoover Dam in southern Nevada. The problem could delay project completion at the drought-ravaged lake by a year and increase costs by “tens of millions,” says a project official.

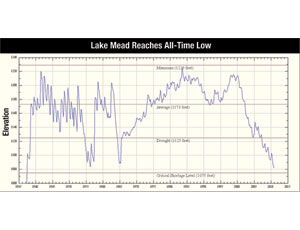

The new intake is intended to draw water deeper from the dwindling lake that reached an all-time capacity low of 38.5% on Dec. 4. Water supplies have evaporated after years of drought and boom growth, a situation that could force the dam to possibly shutter its hydroelectric turbines.

The third water intake, which will draw water from an elevation level of about 1,000 ft., is “our insurance in case our current intakes become inoperable,” says Marc Jensen, Southern Nevada Water Authority engineering director. “It will also draw from lower inside the lake, ensuring better water quality.”

Crews tunneling 600 ft underground on Oct. 27 encountered the water and mud after recovering from a similar incident on June 1 that filled a 200-ft-long, 37-ft-high staging vault and ruined some mining equipment.

General contractor Vegas Tunnel Constructors LLC, a joint venture of S.A. Healy Co., Lombard, Ill., and Impreglio S.p.A., Sesto San Giovanni, Italy, had spent months pumping out water and stabilizing rock fractures with grout in hopes of preventing another incident. Workers had just reached the site of the first mishap when the second one occurred. An emergency bulkhead quickly was installed to prevent the cavern from reflooding. Grouting and geotechnical experts now are formulating a mitigation strategy.

“We have developed a slower methodical approach. A team of experts will do some extensive chemical grout injections and draining to prepare excavating [going] forward,” says Erika Moonin, project manager for the owner, Las Vegas-based SNWA. “It’s too early to tell how long it will take.”

Vegas Tunnel Constructors based its design-build bid on 50 core samples it analyzed, including 33 in the lake itself and another 30 by SNWA. Plans call for building a 24-ft-dia, 3-mile reinforced intake tunnel using a $25-million customized Herrenknecht tunnel-boring machine with a pressurized face for open- and closed-mode operation. The 1,500-ton, 600-ft-long mechanical earthworm will install 2,500 precast supporting rings while removing 260,000 cu yds of material.

The project, awarded in 2008, has yet to use the TBM, although it took 17 months to manufacture and transport the machine from Schwanau, Germany, to the lake jobsite. The contractor will lower components down a 30-ft-dia, 600-ft-long intake shaft and assemble them piecemeal with a jack-and-rail system. Construction crews were still creating a horseshoe-shaped starter tunnel when both breaches occurred. No one was injured in either incident.

A contractual site-conditions clause is under review. The liquidated-damage penalties for the 1,571-day project may run as high as $30,000 a day. The tunnel, the largest component of the multiproject intake, likely will finish a year late, in 2013.

Officials remain hopeful the new intake soon will execute its intended mission. During the past decade, the lake’s water level has dropped from about 1,180 ft elevation to just above 1,080 ft. SWNA’s turbines begin to lose electricity-generating capability when the level drops below 1,075 ft.

Post a comment to this article

Report Abusive Comment