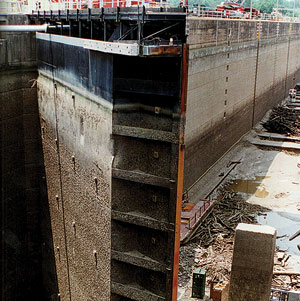

The U.S. Army Corps of Engineers is hastening already-awarded rehabilitation contracts for the Markland Lock and Dam on the Ohio River after the lock’s downstream miter gate detached and sunk to the bottom of the lock chamber. The Corps says a “catastrophic equipment malfunction” on Sept. 27 disabled both 250-ton leaves of the miter gate, taking one off its hinges. It then crashed into the other.

River traffic is shifted to an adjacent, auxiliary lock with half the capacity. That means the many 15-barge tows that pass daily near Warsaw, Ky., must be broken into two operations, doubling transit times to 90 minutes. The Corps had concluded an 11-day inspection of the 1,200-ft-long by 110-ft-wide lock the day before the accident. Corps officials say they found nothing to suggest a failure of the 45-year-old equipment was imminent, although in 2006 the lock moved to high priority for rehabilitation due to its poor condition. An investigation is under way.

Paul Masterson, captain of the sole vessel locking upstream when the incident occurred, says water in the chamber was swirling strangely as he steered in a 96-ft charter yacht. He secured it by a single quarterline to one of the self-adjusting cleats on the wall. “It’s supposed to be dead calm when you enter those chambers [but] there was quite a bit of turbulence,” says Masterson. “It appeared the fill valve was open...but I figured they knew what they were doing.” He says he heard a noise “like an explosion,” followed by two more, but he didn’t look because he was busy trying to control the yacht as currents and swells snatched it around, snapping the 1-in.-dia line.

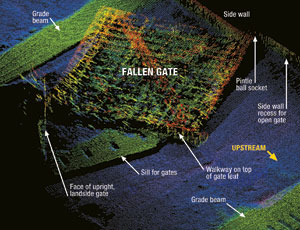

Todd Hornback, spokesman for the Corps’ Louisville District, says the fallen gate has been mapped with sonar. It must be moved off a grade beam so a bulkhead can be seated to permit dewatering. The Corps will use its own gate-lifting ship for that work.

Contracts are already out for a $35-million rehabilitation of the lock. A $17.4 million gate fabrication and assembly contract was awarded in September to Oregon Iron Works Inc., Clackamas, Ore., with an original delivery date of December, 2010. The downstream gate delivery has been pushed to March.

The pace also has picked up on other related contracts funded under the American Reinvestment and Recovery Act. They include $3.6 million to Q.B.S. Inc., Alliance, Ohio, for four valve bodies and two cylinders for culvert valves located beneath the lock chamber; $1.768 million awarded to HTA Enterprises Inc., Vine Grove, Ky., for construction of a pier for staging the gate replacement; and $1.5 million to Climax Portable Machine Tools Inc., Newberg, Ore., for a milling machine to prepare mating surfaces between the gates and chamber.

Post publication correction: The headquarters city named in a previous version of this story for Oregon Iron Works Inc., was corrected to Clackamas, Ore., on 10/9/09.

Post a comment to this article

Report Abusive Comment