When engineers made plans to reinforce and upgrade the carrying capacity of the Empire State Building’s mast and tower by adding 39 tons of steel, they had to find a way to protect pedestrians from falling rivets, tools and materials. Roofing the observatory and building bridges over the sidewalks 1,250 ft below were lousy options. The top of the iconic New York City building has an open-air observatory at the 86th floor and premium viewing spaces at the 102nd and 103rd levels. Annually, these spaces host about 4.3 million visitors and generate about $85 million in revenue. Soaring above the busy streets, a 200-ft-tall steel broadcast tower bristles with antennas that generate about $20 million more. Together, the observatory, mast and tower are the crowning jewel of the 86-year-old icon, which is owned by the Empire State Realty Trust Inc.

|

The search for an alternative to scaffolding dates to February 2014, when the ESRT’s building engineer, engineer-of-record Thornton Tomasetti, site safety engineer Plan B Engineering and contractor Skanska USA Building Inc. began to consult with New York City Dept. of Buildings officials to devise a plan that would not only protect the public and workers but also allow for the strengthening of the mast and tower without having to resort to sidewalk bridges.

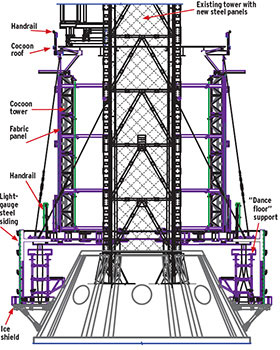

They came up with a design for a sheltering “cocoon,” which sits on a 560-sq-ft aluminum elevated work platform, or “dance floor.” The platform is braced from below by steel brackets through the conical ice shield, which is there to shatter ice falling from the tower.

Further, the outer edges of the dance floor are guyed by cables leading up to the roof of the cocoon and the tower above. Encircling the exposed base of the tower just above the ESB’s roof, the floor is enclosed by walls created by aluminum truss towers arranged in an octagon and bridged by panels of ballistic cloth, which slide in edge tracks from bottom to top. To reduce exposure to dangerous winds, the panels can be drawn down in a few minutes by rollers.

A triangular “Tomcat Truss” tower segment is set in place as the cocoon frame takes form. |

“The planning of the project took two years, including six months to design the cocoon and [perform the wind] testing in Florida,” says Tom Durels, ESRT’s executive vice president and director of leasing and operations. “That gives an idea of the amount of thought and engineering that went into it.”

The assembly is designed to meet city codes for a 300-psf live load and a three-second wind gust of 98 mph. “It was wind-tunnel-tested to failure at 140 miles per hour, and it was the test-sample support structure that failed. It wasn’t the envelope,” says Peter Sjolund, the ESRT’s senior vice president of construction. “You are on the top of the Empire State Building, the most famous office building in the world. You don’t want to be on ‘film at 11.’ ”

Stealthy Work

Scott Seydor was project manager for the cocoon construction. An architect, he joined Skanska USA in 2011 as a design manager for mission-critical, design-build data-center work, which brought him to the attention of Skanska executives looking for someone with a strong design background to manage mission-critical work in the Empire State Building, he says. One one such project, Seydor managed the replacement of the Art Deco mast’s 480 pieces of glass between the 90th floor and 101st floor.

The temporary cocoon structure encloses the base of the broadcast tower as it emerges from the truncated cone at the building’s roof. |

When he heard of the mast-strengthening project, Seydor says he jumped at the chance to manage it, too. “I said, ‘We can do it right. We can do it safe. Let me do it. The project needs to be done.’ ” He adds, “I live in Philly. I get up at 3:30 in the morning because I get to do this. … I am an architect, and this is the most iconic building in the world.”

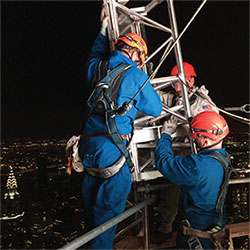

Few New Yorkers—not to mention the hundreds of thousands of annual visitors who meander around the observation decks—are aware of the work being performed above them by a small Skanska USA crew and the handful of steelworkers from Skanska Civil NE, a sister business unit. “It’s such a small space, there’s only so many guys you can throw at it,” Seydor observes.

Because the materials-handling path makes use of the passenger elevators and public observation areas, crews had to construct and, starting this week, will have to deconstruct the cocoon between the hours of 2 a.m. and 7 a.m., when the public spaces are closed.

From the loading dock, materials are navigated through security scanners, down to a lower concourse and up a service elevator to the 79th floor, where they are carted to a passenger-elevator bank for a lift to the 85th floor and then transferred to a manually operated 1930s “mast elevator” for a ride to the 102nd floor. After that, materials are hoisted up ladders and through hatches by hand and with chain falls out through a single “submarine hatch” in the flat-topped conical roof that crowns the building.

Due to handling constraints, including the size of the legacy elevator in the mast, the largest piece taken up was a 6-ft, 4-in.-long W12 steel beam, says ESRT’s Sjolund. A support for the platform framing, it weighs 2,833 lb.

To maneuver beams out of the submarine hatch and into place, the assembly sequence first required the installation of chain hoists on lifting booms projecting from the tower. The steel beams were placed first, building up the ice-shield roof just beyond the perimeter of the planned dance floor. Then, crews erected a hard-sided wall around the first work area to prepare for assembly of the dance floor, just above.

Creating a Safe Space

While there is only a few feet between the cone and the hard side, the clearance creates a small storage area and just enough of a safe space to bolt and splice the hundreds of pieces of aluminum beams, floor plates and vertical truss sections required to create the aluminum floor, towers and roof of the cocoon, which begins just overhead.

The purpose of the work is to increase the steel tower’s carrying capacity by beefing up the lower section of tower above the roof, as well as by reinforcing its ties into the structure. The ironworkers accomplished the work with hundreds of pieces of steel plate and bar of various thicknesses, with the majority of it 1 1/4-in., stitch-welded and bolted to the existing steel. The maximum dimensions and weight of the components are strictly constrained by the tortured logistics required to get them there and the frequent need to fit them between and around the structural features of the existing tower. “If we could have brought up 25-foot-long pieces, we would have loved it,” says Sjolund.

The strengthening work included several phases, the first of which started in fall 2015 and involved strengthening the tower legs as they enter the building’s roof and carry loads down to the 101st level. Crews added bars and plate to the existing steel by replacing rivets with longer torsion-control bolts or fitting plate between existing members and introducing new braces, gussets and diagonals.

On the 101st to 103rd levels, the interior work required opening ceilings, walls and floors in public spaces and was conducted during an around-the-clock, three-week push during February and March 2016. It was the only part of the work that interrupted visitor access to the observatory spaces, and the interruption affected only the smaller, premium spaces on the 102nd and 103rd levels.

Work inside the completed cocoon enabled the next phase of the tower strengthening. “The cocoon allowed us to work uninterrupted through inclement weather and 24/7, without disruption to our broadcasters,” Sjolund says.

To strengthen the tower, crews welded and bolted on additional steel. Further, crews enclosed the lower part of the tower in new steel plate. When workers need to de-energize and service the existing upper antenna array, the new, lower backup antenna array will be used to continue broadcasting and its steel-plate backing will protect the workers from radio-frequency radiation as they climb up.

Antenna Upgrade

The mast’s antennas are licensed to third-party television and radio broadcasters and data communications providers. Further, space in the building’s upper floors is leased to house transmission equipment and related facilities, including “multichannel combiners” that send broadcasts of multiple frequencies through common antenna arrays.

“The planning of the project took two years, including six months to design the cocoon and [perform the wind] testing in Florida”

Nineteen FM radio and about a dozen television channels currently broadcast from the tower. The FM stations use either a primary array about 100 ft above the building’s roof or, lower down, the 50-year-old Alford Antennas backup array, to which signals can be diverted when changes or repairs are needed on the primary array.

Signals are conducted from the channel combiners on a lower floor via 31/8-in.- or 61/8-in.-dia copper-clad coaxial cables in nitrogen-filled jackets. “We call it plumbing—think … of 6-inch-diameter copper pipe,” says Ed Driscoll, the ESRT’s manager of broadcasting. The big copper lines rise through the upper floors and travel up the tower to the antenna. Having run additional lines for the new backup array, the antenna installers will soon start to hang the 4.5-ton backup array on the now-strengthened tower. Work will begin after the cocoon comes down in mid-June.

A 2014 reconfiguration plan mapped out an upgrade to the tower’s antenna-carrying capacity. The addition is driven by market forces, according to the ESRT’s most recent quarterly SEC filing.

“The business of broadcasting TV and radio signals over the air is in flux, due to deteriorating industry fundamentals and the ongoing Federal Communications Commission spectrum auction, and there is competition from other broadcasting operations,” the statement acknowledges. New generations of broadcasting equipment are expected to begin populating the tower in the months and years to come.

Moving On

“One of the things about working on the Empire State Building, the world’s most famous building, is we are constantly innovating and have the benefit of working with the world’s leading experts,” says ESRT’s Durels. “Building this protective cocoon is an example of that,” he notes, adding that the project “may lead others to see what can be done on towers worldwide when it comes to this type of work.”

Seydor will not be around for the cocoon demolition. After years of getting up at 3:30 a.m. and commuting 240 miles a day to lead what he calls a project of a lifetime, the project manager has moved on to work closer to home at Genesis Engineers, Plymouth Meeting, Pa. “It was … an incredible project. They knew it wasn’t just a job to me—it was a passion,” he says. “This is the Empire State Building: Things are different here.”

Post a comment to this article

Report Abusive Comment