Wyoming residents are hoping their resource-based economy will continue to grow and diversify, and they’re investing heavily in their state university to help lead the way. The University of Wyoming’s management of an array of new projects with innovative designs has led to its selection as ENR Mountain States’ Owner of the Year for Colorado and Wyoming.

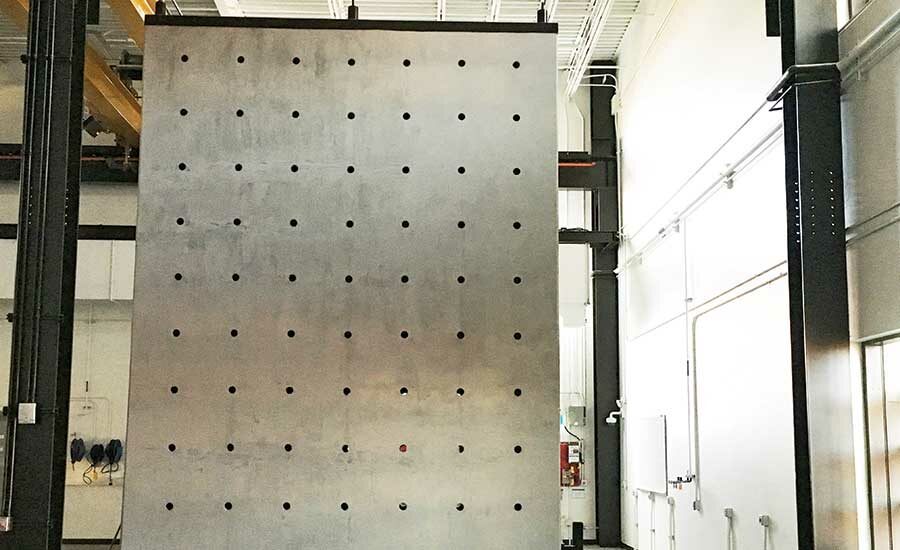

“It’s been an amazing run for facilities improvement here, no doubt about it,” says University of Wyoming spokesman Chad Baldwin. In particular, he points to construction in the university’s science and engineering school, including the new High Bay Research Facility, a $58.7-million, 108,100-sq-ft building that opened in January and will house more than $20 million worth of scientific equipment.

Research there will focus on oil and gas flowing through “tight rocks” such as shale—a linchpin of Wyoming’s economy. But the facility, built by Haselden Construction, is also set up to study the flow of various fluids and a wide range of porous materials—for example, the process of sequestering carbon dioxide in geologic formations.

Energy will be the facility’s primary research topic, says Mohammad Piri, director of the university’s Center for Innovation for Flow Through Porous Media.

Understanding the underlying physics of flow “will be helpful in designing more effective and safer oil-and-gas recovery processes,” Piri says. “The technological challenge is how to provide enough energy for the world’s growing population. We need to have cutting-edge technology to provide fundamental insight into energy recovery from underground hydrocarbon reservoirs.”

Currently under construction is the university’s new Engineering Education and Research Building, the centerpiece in Wyoming’s bid to become a Tier 1 engineering school that, in selected fields, will compete with Stanford, MIT and other leading institutions. Being built by GE Johnson Construction, the $105-million, 109,000-sq-ft facility is scheduled for completion in February 2019.

GE Johnson is also building the $44-million Mick and Susie McMurry High-Altitude Performance Center, an athletic building that will contain 121,000 new and renovated sq ft of space to serve Wyoming’s 400 student-athletes. Included will be a new weight room, a training-table facility, a new locker room for the football team, offices and an academic complex. The building will “just about triple” the university’s current athletic training and administrative space, says Tim Harkins, associate athletic director.

Sletten Construction of Wyoming, located in Cody, is at work on another athletic project, the $17-million, Phase 2 renovation of the university’s arena-auditorium, which seats 11,445 fans for basketball. Included in the project are new ticket offices, an upscale entry facade, a merchandise store, a club area for fans and upgraded concessions stands and restrooms. Also featured will be a statue of Kenny Sailors, a University of Wyoming basketball star who led the Cowboys to the 1943 NCAA championship and is credited with inventing the modern jump shot. Haselden Construction completed the first phase of arena upgrades two years ago.

In that phase, the university reoriented the basketball court and installed new seating in the lower section of the arena. Last year, a new video board was added to the 29,181-seat War Memorial Stadium, the university’s football venue. Previously, the university added 12 suites and 256 club seats to the stadium. All have been sold, according to Harkins.

Economic Boosts

Michael Pishko, dean of the University of Wyoming’s College of Engineering and Applied Science, says the new Engineering Education and Research Building has been designed for flexibility, collaboration and innovation and will contribute to the university’s mission for economic development and diversification within the state.

“We support not only what the current state economy is,” Pishko says, “but also where the state wants to go.” Pishko says current research efforts focus not only on oil and gas but also on wind energy, water resources, supercomputing and artificial intelligence, among other fields.

As for the structure itself, Pishko views it as “simply a tool, a facilitator.” Instead of having auditorium-style classrooms with fixed seating, the building was designed with contemporary teaching methods and collaboration in mind. Floor plans will be open so students can easily configure themselves into teams around work tables. A large atrium will have a variety of purposes, serving not just as a gathering place but also as a theater and a lecture hall.

Trey Nobles, Rocky Mountain Region senior vice president for GE Johnson Construction, likens the building’s concept to that of the modern office, where workers have relatively small personal spaces but lots of room for collaboration.

In particular, the new facility will offer lots of “collision spaces,” where faculty and students can hold impromptu meetings, aided by whiteboards or glass walls and technology such as video screens that can be connected to laptops or tablets. The idea is that students can explore concepts with their professors, and their professors can work together on new research ideas.

Another big science building, budgeted at $103 million and envisioned for 105,000 sq ft, is currently being designed, with completion projected for June 2020. Perhaps less alluring than all the high-tech construction—but still highly utilitarian—will be the university’s $22-million West Campus Satellite Energy Plant, which will provide upgraded heating and cooling. It also is set for completion in 2020.

“It’s been very evident that [the university is] looking way into the future and making sure that they are providing facilities that not only meet the needs of the current student population and handle the current technology but also making sure that they’re set up to provide flexibility when new technology comes out,” says Derek Oliver, Haselden vice president. “They have had a vision for a long time, and it’s been great to see them execute on that vision.”

Matthew F. Kibbon, the university’s deputy director of facilities construction management, says the planning and building process is complex, collaborative and also time consuming, “but allows us to get the best product, without a doubt.”

And with all the work recently completed, currently underway and coming in the near future, Kibbon adds, “It’s a good place to be if you’re in the construction business.”

Post a comment to this article

Report Abusive Comment