Companies worldwide have achieved competitive advantages by utilizing the unique characteristics of an integrated platform of engineering solutions. For example, one of the world’s largest petrochemicals complexes in the Middle East has extensively used modular construction to overcome potential resource risks and cost uncertainties. With a model-based estimating system, this organization was able to understand the cost, risk and resource trade-offs of different design and construction scenarios. The result was an optimized construction strategy, which did not encounter any significant hold-ups in resources or execution.

Similarly, a leading supplier of proprietary process technologies implemented a software environment and new engineering workflow to enable quicker reaction to project proposals. The company saved up to 10% cycle time in engineering hours on repeatable designs and captured best-practice process design templates.

Today’s turbulent marketplace has forced a number of organizations to find new ways to improve inefficiencies in their work process around large capital project bids. One solution has been to implement repeatable engineering designs by adopting cutting-edge engineering software. By integrating this type of engineering approach, companies can achieve best practices and improved economics across the lifecycle of capital projects while remaining competitive.

The right economic trade-off

Most process engineering groups have extensive libraries of previous designs. However, these may not be mobilized for effective re-use. Advanced solutions available today can store completed designs as templates. A crucial factor is the accompanying cost model and the ability to rapidly assemble a new design with the associated costs. For instance, a model-based estimating system can capture engineering knowledge through an “engineer in a box” approach. This powerful tool can capture historical costs, which can then be easily adjusted based upon a new location, different workforce requirements or adjusted project size and scope. This summer, AspenTech conducted a survey of 165 global organizations and found that less than half are satisfied with their current business processes in this area: Only about 30% use such a model-based approach rather than spreadsheets. This demonstrates that the right tools are important for enabling design-re-use business processes.

A standardized design must be scalable and modifiable in several different directions. The most obvious is size and throughput based upon the target yield and economics of the proposed project, as contrasted to the baseline reference project. Project location also has significant impact on civil and structural engineering and determines elements, such as heat-exchanger selection. A standard design will vary based upon specific feedstock. That’s why it’s important to find a solution that integrates process simulation with economic software to enable a proposal team to consider alternative sizes, locations, feedstock and designs, not only in terms of process parameters and specifications, but also in terms of capital and operating costs.

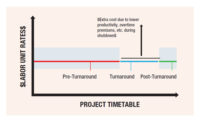

Modular design introduces important opportunities for savings as well as a number of subtle trade-offs between on-site fabrication and shop modular fabrication. When modular construction is being considered, long lead times often become extended due to the need to deliver to the fabrication site, the time to fabricate and then finally ship. Early and accurate conceptual designs become even more important, making it attractive to modify traditional work flows and achieve a fast-track design. Model-based estimating systems are valuable tools in evaluating the efficacy of modules for a given project. On large-scale tasks, the software gives the project team and the client early insight into the resource constraints, such as craft labor and fabrication equipment. The tools can also provide accurate and easy evaluation of shop versus field fabrication, including a whole host of commercial trade-offs.

Best-in-class

Companies today need to rapidly and confidently evaluate capital investment projects early in the design process, understand the economic implications of engineering decisions and effectively manage the project. It’s vital to their cost-efficiency processes to implement integrated engineering modelling and analysis tools that uniquely support the concepts of repeatable, standardized and modular design. These types of tools ensure that data does not need to be re-entered between the engineering tools and enables optimization of a design across the feasibility study, conceptual engineering and FEED workflow, while conforming to normal engineering practices and work business processes. With powerful and integrated engineering software, businesses can make collaborative decisions that dramatically reduce engineering and capital-cost uncertainties helping to deliver best-in-class project execution.

Ron Beck is the Engineering & Construction Industry Marketing Director, AspenTech.

Post a comment to this article

Report Abusive Comment