Tragedy struck the Krsek family on Aug. 1, 2009, when a wind gust blew metal roofing material off an 18-story building under construction in Calgary, Alberta. The projectile killed 3-year-old Michelle Kresk, who was on the sidewalk with her family.

The event “was a wake-up call for the construction industry,” and the city decided to take action to increase public safety near construction sites, says Cliff de Jong, coordinator of issues management in Calgary’s Dept. of Planning & Development.

The next year, Calgary contracted RWDI Consulting Engineers & Scientists—best known as superskyscraper and long-span-bridge wind engineers—to create, maintain and host a 48-hour-in-advance gust-warning system. As of 2012, contractors for buildings five stories or taller pay an additional fee to access the forecasting system as a condition of their permits.

Users, including the city, get email alerts and can view forecasts 24/7 over the internet. Contractors have time to secure sites and defer high-risk lifts.

Article Index:

RWDI, which is paid annually by the city, beat out weather forecasters for the contract because its system provides site-, height- and even equipment-specific gust forecasts. Calling the system leading-edge and remarkably accurate, de Jong says, “RWDI created a fascinating real-world application of science.”

The system first proved itself just months after it went live. On Saturday morning, Nov. 26, 2011, de Jong got an email warning of 150-kilometer-per-hour gusts the next day. That update gave the city 30 hours to prepare. On Nov. 27, officials decided to close off the downtown to pedestrians and traffic from noon until 8 p.m.

Winds did cause damage downtown, but there were no fatalities or injuries and no incidents related to construction sites. “We would absolutely recommend this system for any municipality that has high-rise construction,” says de Jong.

Based on the Calgary experience, RWDI is planning to market gust-warning systems to cities in the U.S. and Canada. That’s a common strategy of the 455-person Guelph, Ontario-based firm: Innovate for one client and tailor the innovation for others. RWDI’s overarching goal is to create safer, more comfortable and more sustainable habitats—indoors and out.

The modus operandi has resulted in more than 20 developments in wind engineering and environmental science since the 1972 formation of RWDI’s predecessor firm, Morrison Hershfield Theakston and Rowan. MHTR was the first commercial test laboratory in snow and wind engineering. Earlier labs were at universities.

|

Click Here to Read RWDI Takes Wind Engineering to New Heights |

“They are always improving,” says David Goodyear, chief bridge engineer for TY Lin International, which used RWDI on all of its 12 long-span bridges since 1991. “Their analytics and model-testing expertise in aerodynamics is unsurpassed,” he says.

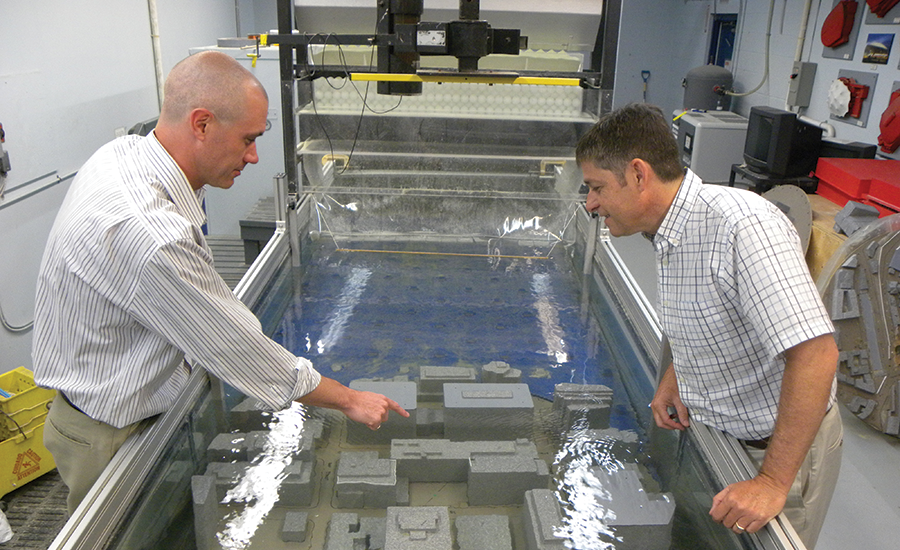

An early innovation is the water-flume snow-drift simulator, still a mainstay today, says Peter A. Irwin, RWDI’s chairman and a founding partner, in 1986, of Rowan Williams Davies and Irwin Inc. Irwin, 70, a renowned wind engineer, joined MHTR in 1980.

Other RWDI achievements include the omni-directional Irwin Sensor for wind-tunnel studies of pedestrian level winds, invented by Irwin during his earlier tenure at the National Research Council Canada and adopted by MHTR. The sensor was then used, in the 1990s, to develop thermal-comfort criteria for assessing pedestrian wind comfort, says Irwin.

In 1985, the firm, named Morrison Hershfield from 1982 to 1986, rolled out the finite-area-element method for predicting snow loading, which subsequently was used to develop snow-load provisions for the 1995 Canadian Building Code and, since then, has been applied to long-span roofs. Recently, RWDI has used the method to develop load combinations of wind and snow.

A decade later, RWDI undertook the first use of the high-frequency pressure-integration method for testing tall buildings, stadium roofs and canopies and verified that it compared well with traditional methods—limited to tall buildings—that use a force balance at the base of the model. HFPI, currently widely used, integrates data from hundreds of pressure taps on a model to obtain overall loads on the main structure.

“It improves results on very slender buildings and on those with large torsional loads,” says Irwin. “It can also be used on linked towers.”

In 2003, for Dubai’s 828-meter-tall Burj Khalifa—the world’s tallest building—RWDI first applied meso-scale meteorological modeling to a major wind assignment. For studies of the 1-km-plus Jeddah Tower, which just reached 180 m, RWDI developed computer-based tools to estimate wind behavior at the top of the tower, which will extend above the range of the earth’s boundary layer addressed in codes (see p. 36).

“They are brilliant,” says Hisham Jomah, chief development officer for the Jeddah Tower’s Jeddah Economic Co.

For long-span bridges, RWDI developed the tensioned-tube testing mewthod, used on the ALRT Bridge in Vancouver, British Columbia, and the Golden Gate Bridge in San Francisco.

For habitats, RWDI in 2014 introduced its urban-environment simulator, a digital tool that simulates wind and solar impacts for all hours of any meteorological year. The results can be manipulated into predictions of wind and thermal comfort, daylighting potential, heat transfer into and out of buildings, urban heat-island effects and more, says Duncan Phillips, an RWDI senior consultant and project director.

In 2000, with the formation of sister company Motioneering, RWDI began the design, fabrication, installation and commissioning of custom damping systems for tall buildings. These include tuned mass dampers (TMDs) near the tops of the 508-m Taipei 101 and the Western Hemisphere’s tallest residential building, the 1,396-ft-tall 432 Park Avenue in Manhattan. RWDI commissioned the 432 Park TMD last month.

Jon Galsworthy, RWDI principal and general manager of the wind loads and effects group, realizes there could be an appearance of a conflict of interest if an RWDI wind engineer recommends a TMD that Motioneering might supply. “We talk about it up front,” says Galsworthy, 43, who is described by designers as a “young Peter Irwin.”

Usually, there isn’t an issue because RWDI is trusted and respected by the owners and developers that hire the firm and by its designer-collaborators, which often recommend RWDI. “They are consummate professionals,” says TY Lin’s Goodyear.

Gareth Newlands, director of infrastructure development for construction service firm Carillion Canada, adds that RWDI’s people are “consistently the smartest in the room” and deliverables are “always early.”

For superskyscrapers—buildings taller than 300 m, “they are tops in their field,” says Peter Weismantle, director of supertall building technology for Adrian Smith + Gordon Gill Architecture LLP, designer of the Jeddah Tower. “They do a good job of explaining the intangibles,” he says, so much so that AS+GG often brings RWDI in at the design-competition stage.

Dennis C.K. Poon—vice chairman of structural engineer Thornton Tomasetti, which has worked with RWDI on 10 supertowers, including Jeddah Tower—adds, “RWDI has top management and top scientists.”

The only complaints about RWDI are that the firm can be too busy and that Guelph, where they have 273 staff and three wind tunnels, is 43 miles west of Toronto “in the middle of nowhere.”

Even then, Silvian Marcus, a director of structural engineering for WSP Parsons Brinckerhoff USA, describes two “reluctant” day trips to Guelph—each for a designer-developer workshop to rescue a supertower project, one of which was 432 Park Avenue—as “well worth” the time, expense and inconvenience.

“Each workshop was a last resort to make the structure work,” says Marcus, who describes as “exasperating” some of the wind-tunnel trials with tweaked models. But, in the end, “a solution was found, everyone was happy, and I made the last flight back to New York,” he says.

RWDI’s supporters are careful to point out that they routinely consider using other wind engineers. RWDI competitors include the Boundary Layer Wind Tunnel (BLWT)—founded by the late Alan G. Davenport—at the University of Western Ontario; CPP Wind Engineering, founded by the late Jack E. Cermak; and the global BMT Group.

“We’re very happy to have RWDI with us in the marketplace because the two of us together can move technology and innovation forward,” says Oliver Napp, CEO of the 100-plus-person Fort Collins, Colo.-based CPP, which is the only U.S.-based commercial wind consultant.

Risk Mitigation

Though best known for wind engineering on structures to help render them safe, serviceable, efficient and economical, RWDI has long offered environmental services to improve habitats. These services include snow, ice, rain and sand control; acoustics and noise control; air-quality control; and exhaust and ventilation studies.

Other services include forensic studies, meteorological studies, pedestrian-comfort studies, glare mitigation and daylighting studies and energy modeling. Environmental hazard and risk mitigation and regulatory permitting services also are available.

Of late, RWDI looks at projects through a sustainability lens. “Ultimately, wind engineering is about total climate design,” says Phillips.

The ability to measure and model indoor and outdoor climate variables and then assist in a holistic design solution will gain importance, he adds. An example is a natural ventilation system that insulates occupants from external noise and pollutants while providing good airflow, daylight and comfort.

Albert Brooks, RWDI’s microclimate coordinator, says the wind engineer’s role should morph from a service provider to an integral member of a project team, providing guidance at all stages. Toward this end, like many specialty consultants, RWDI is trying to get on teams during conceptual or schematic design.

“We can provide [advice] up front, possibly even reducing the number of tests needed,” says Michael J. Soligo, RWDI’s president and CEO.

Long-span and tall structures always will be a mainstay, Soligo adds. RWDI has done wind engineering for seven of the 10 tallest completed buildings.

“We use them more than any other wind-tunnel [engineer],” says William F. Baker, structural engineering partner for architect-engineer Skidmore Owings & Merrill. For the Burj Khalifa, SOM even used the wind tunnel as a design tool to better shape and orient the tower.

RWDI has been developing digital airflow modeling tools—based on computational fluid dynamics—for a quarter century. Though CFD is playing a larger role in visualizing wind flow, especially when modeling internal building flows and stack-and-mechanical system effects, digital simulations likely will not replace the wind tunnel any time soon, thanks to improved wind-tunnel techniques and testing schedules.

“Coming through the wind tunnel is the gold standard to get wind-loading information specific to a project,” says RWDI’s Galsworthy.

For wind loads and effects, CFD is helpful in applications when understanding the broad strokes of a problem is sufficient to evaluate options. “Where it still falls short is predicting actual wind-induced pressures on structures subjected to wind,” says Galsworthy. “The scale of the computational domain is still beyond the reach of affordable computing power.”

RWDI’s largest wind tunnel is 24 ft wide, 8 ft tall and 150 ft long. At the ends of each rectilinear tunnel, fans either blow from upwind or suck from downwind of the test section, placed near the downwind end. Tunnels are outfitted with cameras, and clients can view tests online.

Scale models, produced by RWDI, are mounted on a turntable that can rotate 360° to simulate wind directions. For buildings, the surrounding buildings are included to study aerodynamic effects on the test model, which is outfitted with 500 to 1,000 transducers to measure pressure points and strain gauges to measure forces.

For long-span bridges, testing typically starts with a sectional model mounted on a spring suspension system. Full scale-model tests follow.

Wind speeds usually are scaled down in the range of zero to 20 meters per second. Instrumentation is linked to a digital data-acquisition system for subsequent analysis.

Fee Reductions

The privately held RWDI does not release specifics about finances, but CEO Soligo says that, since 2012, internal share value has quadrupled and revenue has doubled. “Our profitability is six times greater than four years ago,” he says.

RWDI has been able to reduce fees by 20% to 25% due to recently implemented internal efficiencies in process and technology. Sustainability is the fastest-growing market sector, says Soligo.

In 1986, when a group led by cofounders Bill Rowan, the late Colin J. Williams, Anton Davies and Irwin bought out MH’s Guelph microclimate division, they were MH senior partners. Rowan is retired and not available for comment. Williams died of cancer in September 2014, at age 66. Davies, 67, who joined MHTR in 1977, set up the first wind tunnel.

Davies’ colleagues consider him the firm’s global ambassador. “I hop on his coattails and ride them” to gain entrée to the best designers, says Mike Williams, an RWDI associate in sustainability and the 36-year-old son of cofounder Colin. “Anton has traveled the globe more than anyone I know.”

Irwin, called “the cerebral one,” currently works 10 to 15 hours a week on RWDI projects. His other job is professor of practice at Florida International University’s Wall of Wind facility in Miami, where he supervises and advises on wind engineering research.

Soligo, RWDI’s most intense cheerleader, joined in 1988 and developed the sports-and-entertainment venue sector, which he still leads. He has been at the helm since 2009, when he took over from Irwin.

Thanks to the Great Recession, “it was baptism by fire,” he says. Soon, the staff shrank to 300 from 400. But Soligo says the hard times provided the opportunity to make RWDI a more efficient organization.

RWDI’s Guelph staff, currently in two locations, is set to move into a 130,000-sq-ft facility on Aug. 1. In addition, RWDI has staff in 19 locations, including offices in Milton Keynes, England; Calgary; Vancouver, British Columbia; and Trivandrum, India. Environmental services has 116 staff; followed by loads and effects, with 97; and building science, with 74. The rest of the staff is in corporate or production resources, which includes model makers.

RWDI’s ethos is still informed by the academic roots of MHTR, whose founders taught at the University of Toronto. RWDI has 75 engineers educated in Canada, including several PhDs— Davies, Irwin and Galsworthy, among them. During his earlier tenure at the BLWT, Galsworthy taught at the university.

The firm’s sensibility also is shaped by a 94-year Canadian tradition—the Ritual of the Calling of an Engineer—intended to instill a sense of duty to society and foster fellowship. In a college graduation ceremony, an engineer places a faceted pinky ring on a graduate’s “working hand” to be “an ever-present reminder of obligations” to public safety, says Mike Williams. In 2004, his father presented him with an “iron ring.”

RWDI’s increased focus on sustainability is a big reason Mike Williams decided to meet his destiny and join the firm. That was in 2014, five months before his father died. He sees his future at RWDI.

Jason Munn—a 29-year-old market-sector leader for sports and entertainment venues—had a tougher time getting noticed at RWDI. In 2010, when the recent chemical-engineering graduate applied for jobs, he got no reply. Undaunted, he paid an unscheduled visit to speak to someone. He soon got an offer.

“We do cool stuff,” says Munn. “Most of my peers don’t get to walk into a wind tunnel.”

Albert Brooks, RWDI’s 29-year-old microclimate coordinator, also loves his work. For cold-climate jobs, he is often in a climatic wind tunnel, where the temperature will be -20°C, not counting wind chill and effects of freezing rain. “I have had the privilege of investigating the accretion and shedding characteristics of vertical and horizontal sun shades, bridge stay cables and railings, facade mock-ups and more,” says Brooks.

Looking in a crystal ball, RWDI’s next generation—Munn, Brooks and Williams, among others— envision virtual-reality simulators, virtual wind tunnels and other experiential devices to better convey complex wind phenomena. They also expect improved computing to deal with climate change.

Williams sums it up, saying, “As stresses on the natural environment increase, I see a need for wind engineers to help create structures that have zero impact and perhaps even begin to restore the environment.”

Post a comment to this article

Report Abusive Comment