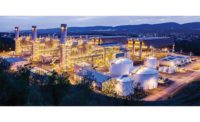

Wisconsin Power & Light Co.’s largest coal-fired power plant, Columbia Energy Center, with two subcritical units over 500 MW, was required to bring its air emissions into compliance with federal standards. The utility engaged Black & Veatch to engineer, procure and construct a $589-million, state-of-the-art air-quality-control retrofit. To reduce mercury and sulfur dioxide emissions, new equipment included a carbon-injection system, a semi-dry flue-gas desulfurization system and a pulse-jet fabric filter. Common equipment at both units included a reagent preparation system, a truck-based lime delivery station and storage silos, scrubber solids-handling and conveying system, and ancillary equipment.

The contractor’s voluntary partnership with OSHA proactively reduced hazards for the 750 personnel on site, project officials note. “We implemented a wide variety of best industry practices,” says Jeff Kurtz, Black & Veatch vice president and project director. “This included the strong involvement of craft supervision and [craftspeople] in ensuring a safe work environment. As part of this effort, we conducted regular safe-work surveys with craftworkers to identify any potential safety issues that needed to be addressed. As a result, there was a strong commitment across our entire workforce that safety was the No. 1 concern in the successful completion of this major project.”

The project logged more than 1.9 million work-hours with no lost-time incidents. The equipment now functions with 99% or better reliability.

Columbia Energy Center Air-Quality-Control Retrofit

Pardeeville, Wis. Region Midwest

Project team

Owner Wisconsin Power and Light Co., a subsidiary of Alliant Energy

Lead Design Firm/Contractor Black & Veatch

Post a comment to this article

Report Abusive Comment