Building and designing Las Vegas’ new MGM/AEG-owned T-Mobile Arena to match the ambiance and style of the city inspired the project team to create cutting-edge elements—including dual cantilever balconies over the upper bowl and exterior balconies—while working quickly.

Managed by a Hunt-Penta joint venture, construction on the privately funded, 20,000-seat, $375- million indoor arena began in 2014. The 16-acre site and 650,000-sq-ft structure sits west of the Las Vegas Strip between the New York-New York Hotel & Casino and the Monte Carlo Resort and Casino. Running the overall job is project manager ICON Venue Group, with Populous as the architect-of-record. Meanwhile, Thornton-Tomasetti is acting as the structural engineer, with SME Steel backing the steel construction.

Exclusive Views

One of the most visible exhibitions of a new engineering application are three balconies that are outside the arena but accessible after a patron gains entrance. A fourth balcony is designed to host bands and other performers for outside events in the expansive plaza that leads into MGM’s adjacent $100-million development, The Park. The balconies are supported by plate girders and trusses attached to the structural steel of the arena.

In order to control vibration on the main exterior balcony, the design team implemented plans that included tuned mass dampers under the exterior balcony.

The exterior balconies are directly in front of the 85-ft-tall glass atrium, which curves outward due to the arena’s elliptical shape. Y-shaped columns support the glass.

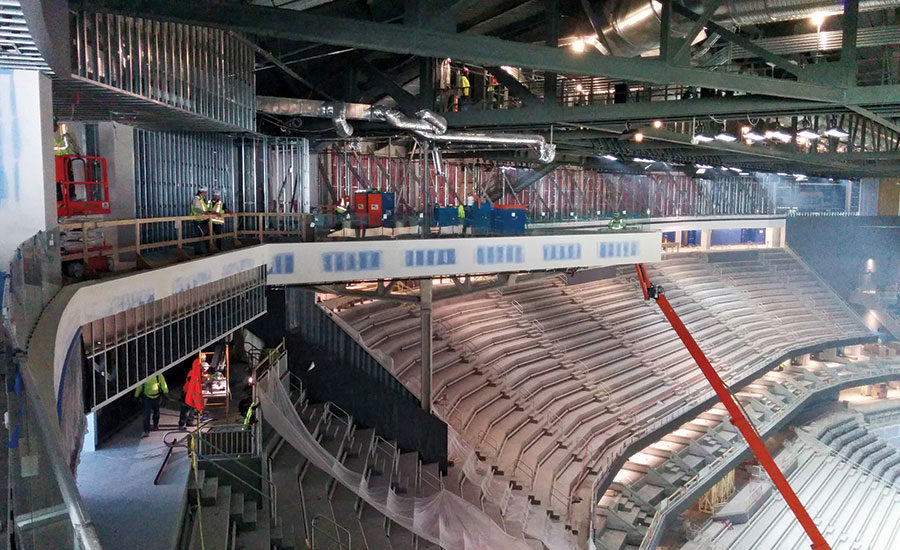

Inside the arena, northeast and southeast balcony lounge areas extend over the upper bowl. They are the most ambitious take on such a feature in any arena, according to Brad Clark, senior principal at Populous. They are triangular in shape, and the support system is a hybrid cantilever design. A single column helps to support the balcony, but the tips of the triangle nearly reach the inboard edge of the upper bowl.

“We really pushed the engineering of that piece as much as we could, but there is a support column,” says Clark. “Anyone that goes out [on one of the balconies] is so taken by the view that they don’t even notice the column.”

The two Tower Clubs and their balconies flank a larger lounge space.

Adjustments Happen

The final design called for about 200 piers. The entire project included more than 7,000 pieces of steel, weighing more than 7,100 tons in total. According to the project team, the 350-ft-long main trusses support a 200,000-lb-capacity rigging grid, which is used for hanging equipment for concerts and events. The long roof span clears the seating bowl and creates a column-free space and unobstructed views.

“There were a lot of buried treasures.”

—Mitch Bernard, project manager, Hunt-Penta

For the construction and design teams, the switch from concrete to a predominantly steel structure impacted interior work more than any other area, as, initially, many elements had been designed to be exposed concrete. As a result, lighting elements and finishes were used to mask the fireproofed steel, says Tracy Tapp, principal at Populous.

At two ends of the site, pier installation was complicated by the underground presence of power and fiber-optic cables for several resorts, casinos and other businesses. Preconstruction testing also revealed extensive caliche, which resulted in tough digging chores for the construction crews. A handful of spread footings also were used in light-load areas.

“There were a lot of buried treasures,” says Mitch Bernard, project manager at Hunt-Penta. Crown Corr, Gary, Ind., is the enclosure subcontractor. Populous and the construction team worked together to bring the exterior design drawings to life.

The cladding on the sides and rear of the arena was assembled from approximately 19,000 sq ft of custom-fabricated metal shingles and 140,000 sq ft of insulated panels that are visible on the inside.

Moving People

The upper bowl of the arena is designed to load from the top, allowing for maximum seating capacity when set up for concerts.

For the vast majority of event attendees, the main promenade, located beneath the two exterior balconies, will provide ingress and egress. Two VIP entrances will whisk suite owners and other high-profile patrons to the event-level “bunker” suites or to the suite level. As part of this effort, Thor Construction built an elevated walkway from the New York-New York parking garage.

As of early February, there were more than 700 workers on the site each day, working in two shifts. About 450 workers were on the site before January 2016, when a baked-into-the-schedule ramp-up began, says Monte Thurmond, vice president at Hunt-Penta.

“We have a lot to do between now [February] and the end of March, and we always knew we would have a lot to get done between February and March,” says Thurmond. “The schedule on this project has been aggressive from the beginning.”

Because the facility is near several hotel towers, work was mostly limited to two shifts. Approximately 38 supervisors managed day-to-day activities. After topping out two days early in May, work has progressively transitioned to the interior of the structure.

“We, literally, have work being done on most every room and on most floors,” Thurmond says.

As of late February, more than 1.4 million worker-hours were logged on the job with no lost-time and only 12 recordable incidents, according to Bernard. The construction team put more than 4,500 employees through a site-specific safety program.

The facility also was designed with a target of acquiring LEED Gold certification from the USGBC.

Construction is anticipated to be complete in late March. The April 6 opening-night event will feature The Killers and Wayne Newton.

Post a comment to this article

Report Abusive Comment