Denver Water will begin construction next month on an ambitious $100-million, four-year project to replace an aging pump station and concrete storage tanks in south Denver near the intersection of I-25 and I-225.

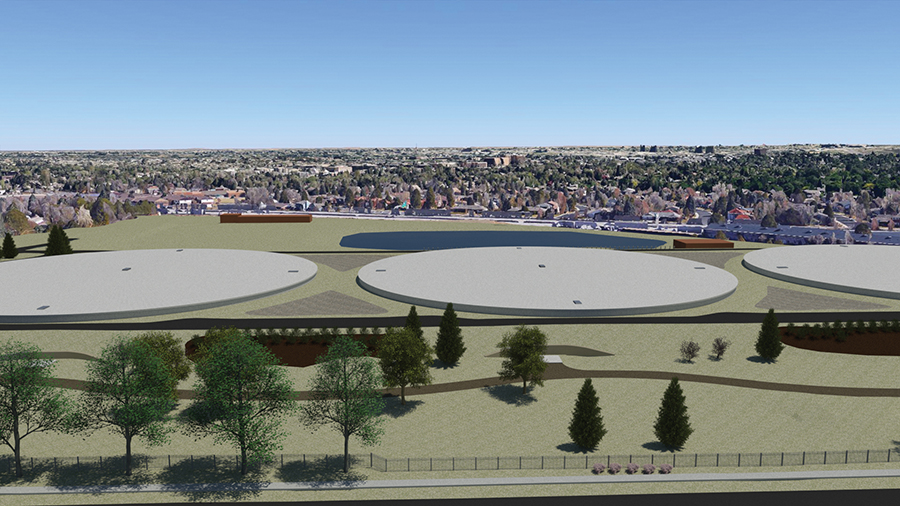

The Hillcrest Reservoir Tank and Pump Station Replacement Project will remove two conventionally reinforced concrete storage basins built in 1960—with a combined capacity of 30 million gallons—and replace them with three circular, prestressed, tendon-type concrete basins with a combined capacity of 45 million gallons.

The project also replaces the facility’s 1963 pump station with a new one that has a capacity of 115 million gallons per day. Hillcrest serves thousands of customers in the south Denver area.

“The basin replacement portion of the project is the capstone of a multi-year, $130-million program to improve the reliability and capacity of our treated water storage system,” said Bob Mahoney, director of engineering for Denver Water, in a statement. “The updated facility will help meet the needs of a growing population, which has placed increasing demand on Hillcrest Reservoir’s aging storage and pumping facilities.”

The new Hillcrest system will also provide more flexibility for daily operations, says Martin Garcia, design project manager for Denver Water. Hillcrest will remain operational throughout the project except for a few scheduled shutdowns. The workflow will be tricky, he says, because the site is surrounded on three sides by residential neighborhoods, so “the key is to keep residents well informed about construction activities.”

Initial work will replace older fences with temporary sound barriers to mitigate construction noise. At the end of the project, the sound barriers will be removed and replaced with “upgraded, more uniform neighborhood fences,” Garcia says.

After initial excavation, crews will first install yard piping, then place the new concrete tanks, which are located within 100 ft of the older ones, says Dan Batt with the engineering division of Denver Water’s construction management section. They will build two of the new tanks, then demolish the older ones, followed by construction of the third new tank, and then the new pump station. Demolition of the old pump station will happen after the new one is on line, Batt says. The project is slated for completion in late 2020.

The “integrated design” project is being led by MWH Constructors, a subsidiary of MWH Global, headquartered in Broomfield, Colo., under a construction-manager-at-risk contract.

Other key team members include OZ Architecture, which is designing the new pump station; the Denver office of Brown and Caldwell; Bates Engineering Inc.; PEI and Life Time Fence Inc., among others.